Tel/Whatsapp: +86-13013179882 Email: futao@orinkoplastic.com

PBT

ORINKO

ORINKO PBT GF30 is a high-performance engineering plastic compound based on Polybutylene Terephthalate (PBT) resin, reinforced with 30% glass fibers. This combination delivers an exceptional balance of properties, making it a versatile material for demanding applications across various industries.

Key Features and Benefits:

Enhanced Mechanical Strength: The 30% glass fiber reinforcement significantly improves tensile strength, stiffness, and impact resistance compared to unfilled PBT.

Excellent Dimensional Stability: ORINKO PBT GF30 exhibits low shrinkage and warpage, ensuring precise and consistent part dimensions even under varying temperature and humidity conditions.

Superior Heat Resistance: This material maintains its mechanical properties at elevated temperatures, making it suitable for applications requiring thermal stability.

Good Chemical Resistance: ORINKO PBT GF30 demonstrates resistance to a wide range of chemicals, including oils, greases, and solvents.

Excellent Electrical Properties: The material possesses good dielectric strength and volume resistivity, making it suitable for electrical and electronic applications.

Automotive Industry: Modified PBT is primarily used in automotive components such as wiper brackets, headlight bezels, transmission gearboxes, windshield top bollards, and motor housings.

Electronics and Appliances: PBT is widely utilized in the electronics and appliance industry for components like electronic connectors, cooling fans, and the bases and housings of energy-saving lamps. Its popularity stems from its excellent mechanical properties, solvent resistance, good moldability, and cost-effectiveness.

Electrical Industry: PBT is suitable for manufacturing transformer components, relay spools, and housings, as these require materials with superior insulation, heat resistance, flame retardancy, high fluidity, strength, and toughness.

Other Applications: PBT is also used in the production of skate soles, sockets, switches, tuner housings, vacuum cleaner components, electric fans, hair dryer housings, fiber optic connectors, and more.

Insulation Fram

Rotor

Fan Blade

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

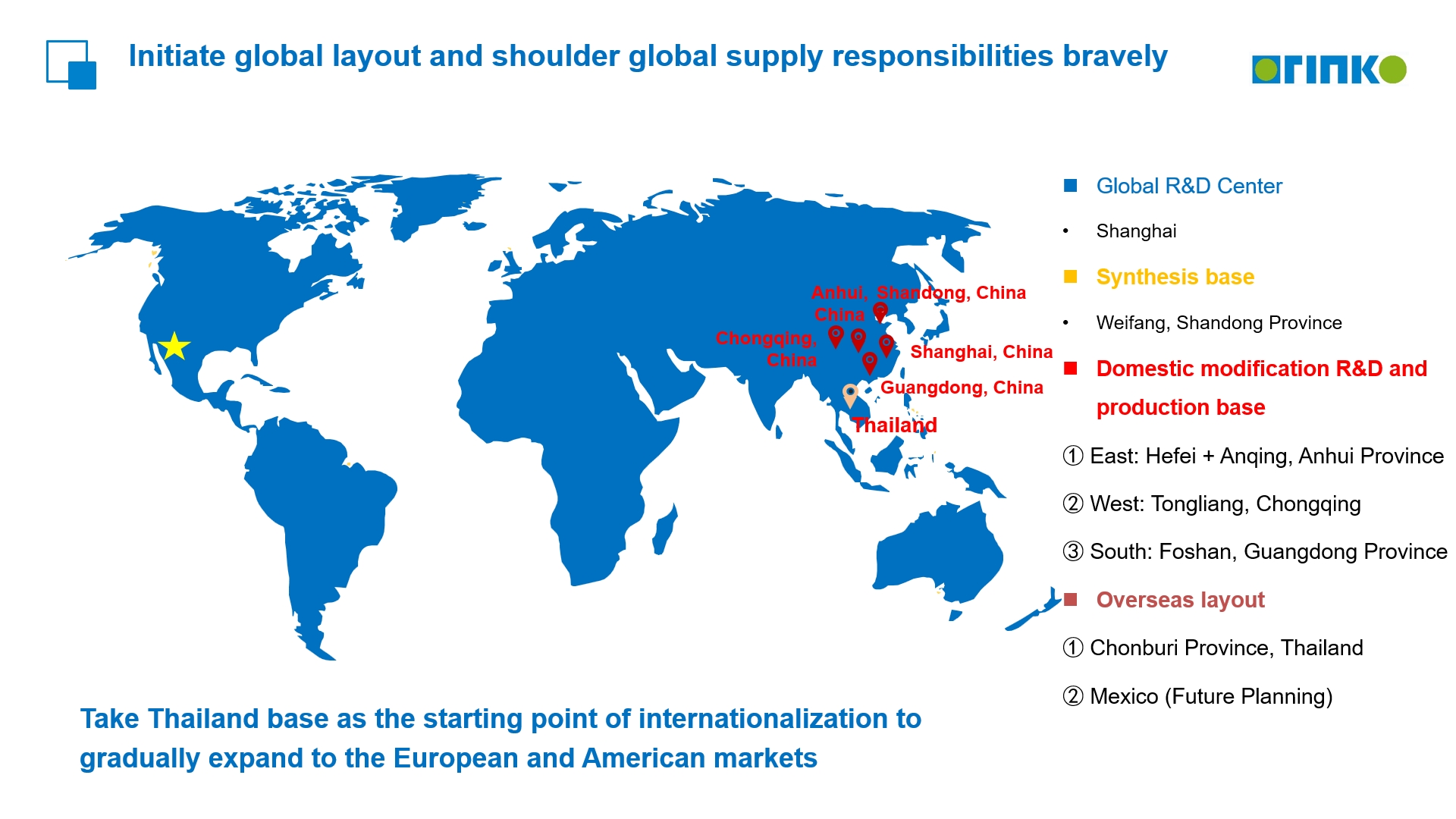

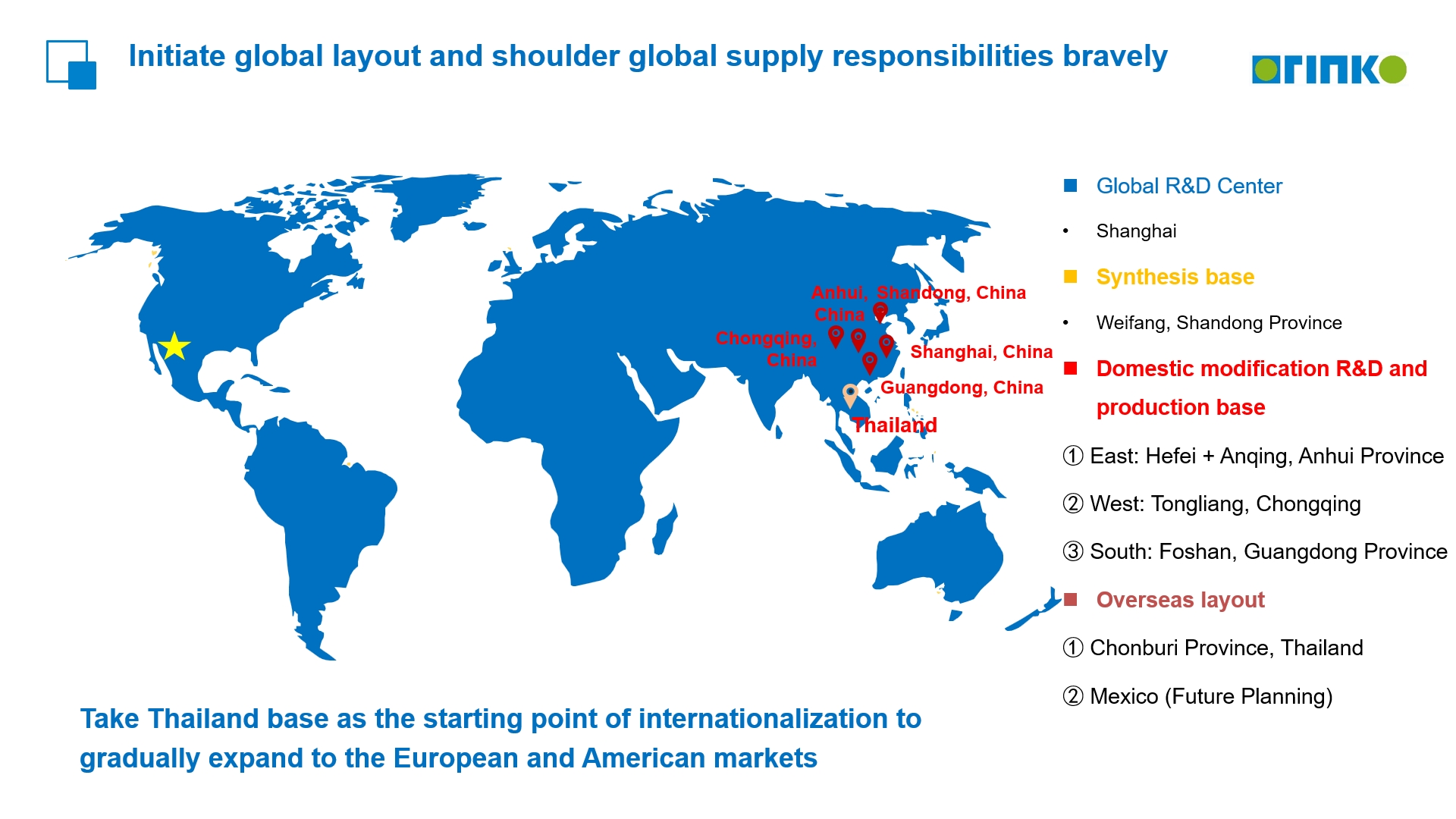

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

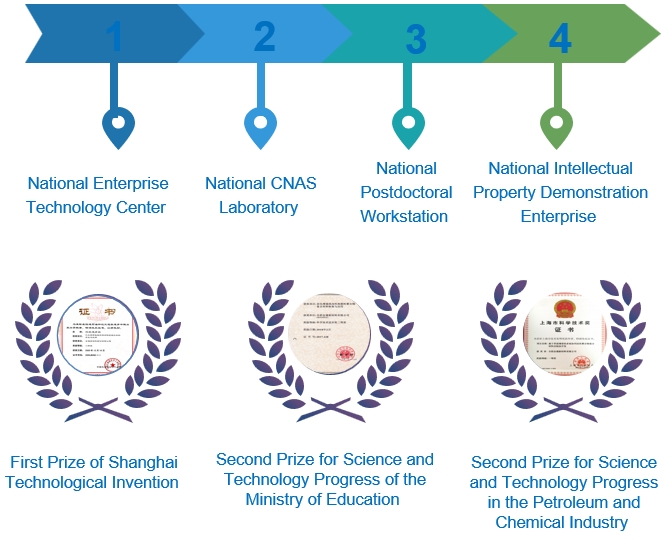

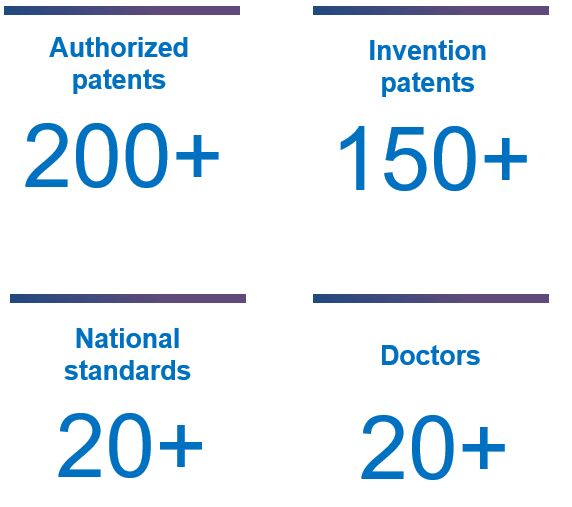

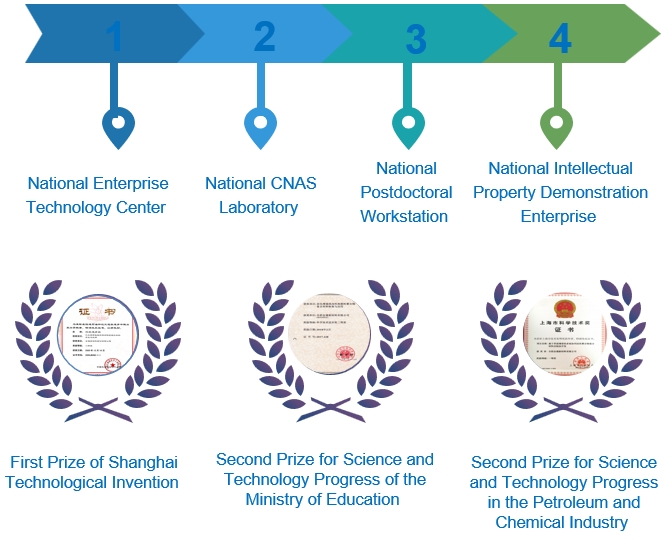

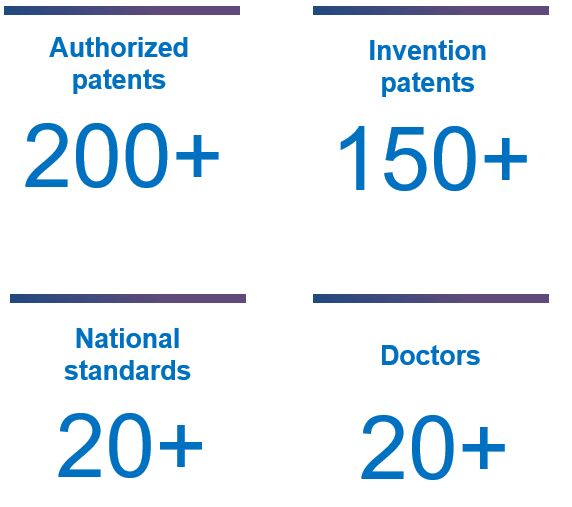

Inject impetus into the enterprise and industrial development with continuous innovation investment

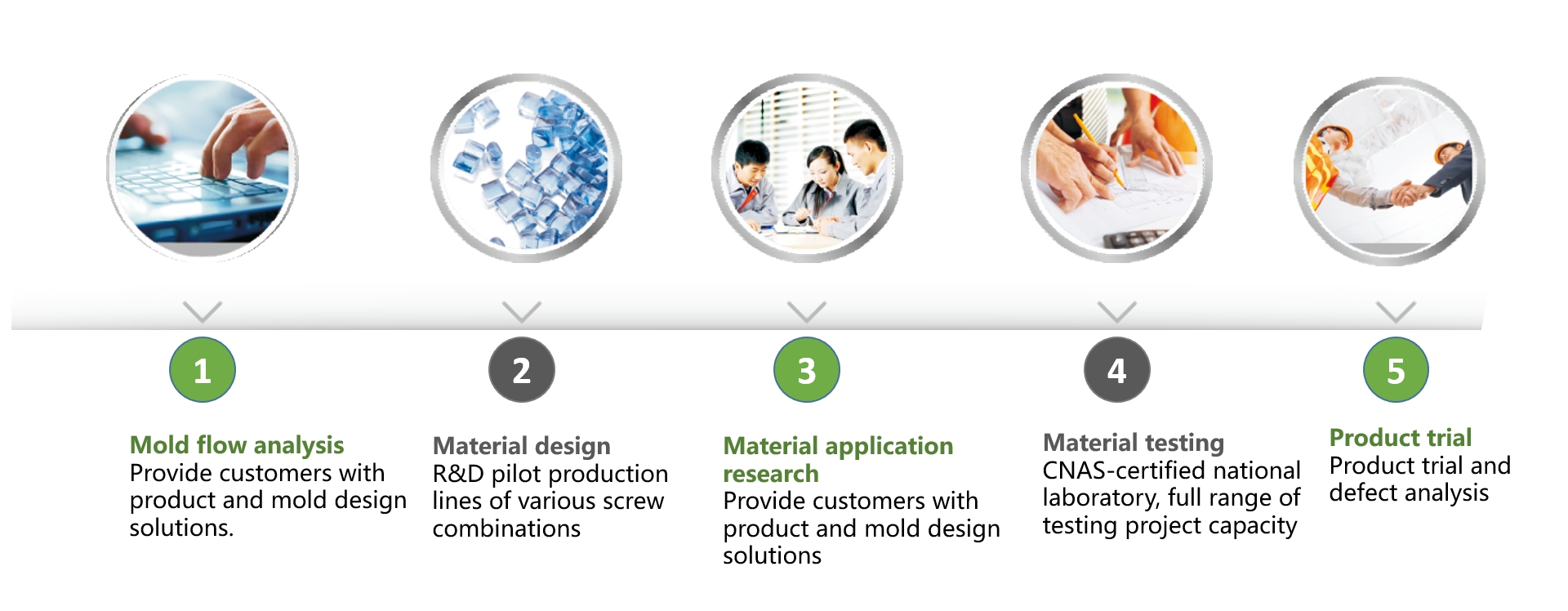

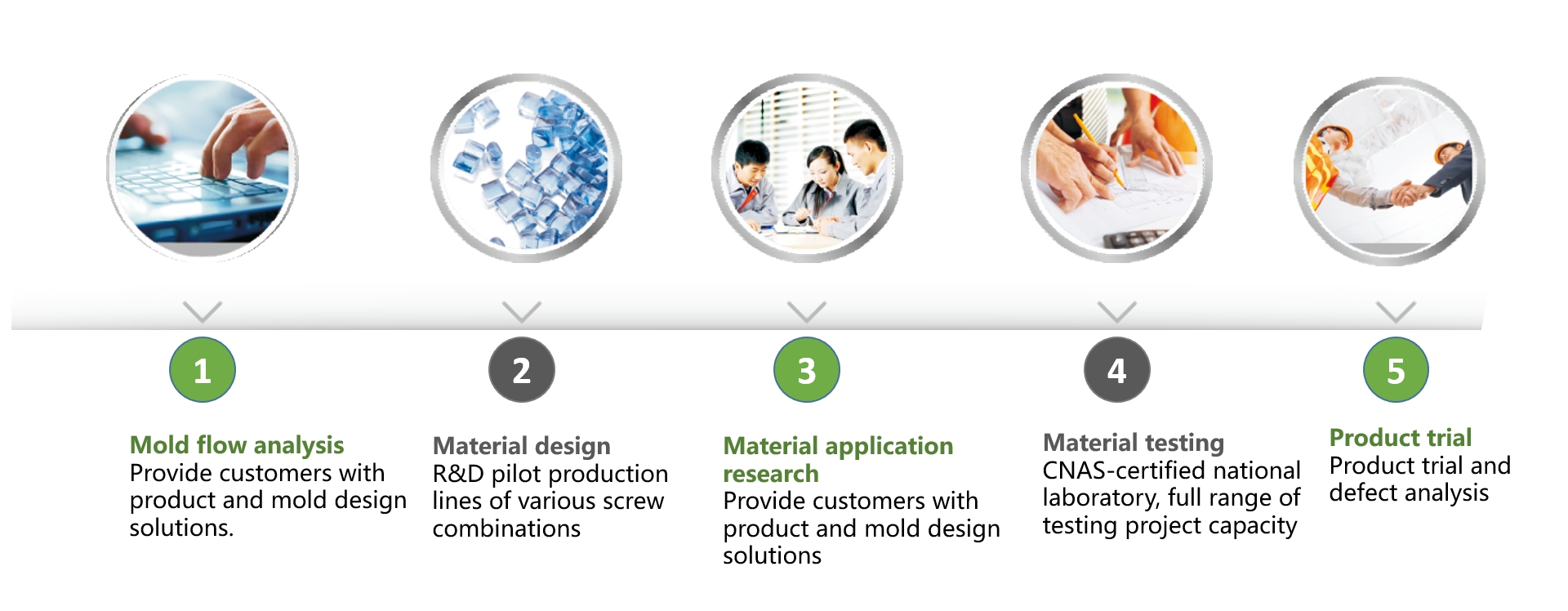

Innovation capability-provide overall solutions

Contact us

Email:futao@orinko.com.cn

Whatsapp/Wechat:+86 13013179882

ORINKO PBT GF30 is a high-performance engineering plastic compound based on Polybutylene Terephthalate (PBT) resin, reinforced with 30% glass fibers. This combination delivers an exceptional balance of properties, making it a versatile material for demanding applications across various industries.

Key Features and Benefits:

Enhanced Mechanical Strength: The 30% glass fiber reinforcement significantly improves tensile strength, stiffness, and impact resistance compared to unfilled PBT.

Excellent Dimensional Stability: ORINKO PBT GF30 exhibits low shrinkage and warpage, ensuring precise and consistent part dimensions even under varying temperature and humidity conditions.

Superior Heat Resistance: This material maintains its mechanical properties at elevated temperatures, making it suitable for applications requiring thermal stability.

Good Chemical Resistance: ORINKO PBT GF30 demonstrates resistance to a wide range of chemicals, including oils, greases, and solvents.

Excellent Electrical Properties: The material possesses good dielectric strength and volume resistivity, making it suitable for electrical and electronic applications.

Automotive Industry: Modified PBT is primarily used in automotive components such as wiper brackets, headlight bezels, transmission gearboxes, windshield top bollards, and motor housings.

Electronics and Appliances: PBT is widely utilized in the electronics and appliance industry for components like electronic connectors, cooling fans, and the bases and housings of energy-saving lamps. Its popularity stems from its excellent mechanical properties, solvent resistance, good moldability, and cost-effectiveness.

Electrical Industry: PBT is suitable for manufacturing transformer components, relay spools, and housings, as these require materials with superior insulation, heat resistance, flame retardancy, high fluidity, strength, and toughness.

Other Applications: PBT is also used in the production of skate soles, sockets, switches, tuner housings, vacuum cleaner components, electric fans, hair dryer housings, fiber optic connectors, and more.

Insulation Fram

Rotor

Fan Blade

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

Inject impetus into the enterprise and industrial development with continuous innovation investment

Innovation capability-provide overall solutions

Contact us

Email:futao@orinko.com.cn

Whatsapp/Wechat:+86 13013179882

No.2 Luhua Road,Boyan Science Park,Hefei,Anhui Province,China