Tel/Whatsapp: +86-13013179882 Email: futao@orinkoplastic.com

| Availability: | |

|---|---|

| Quantity: | |

PA610

Orinko

ORINKO Polyamide 610 (PA610)

is a long-chain nylon, which is made by condensation polymerization of ethylenediamine and dodecanedioic acid as raw materials. The raw material dodecanedioic acid can be produced through chemical synthesis or microbial fermentation. ORINKO integrates PA610 forward and backward, with our own factories in backward raw material production, forward resin polymerization and polyamide compound.

Polyamide 610 Resin: Unrivaled Thermal Stability

Polyamide 610 (PA610) resin stands as a testament to superior thermal stability, making it a standout choice among thermoplastics for applications where exposure to elevated temperatures is a critical consideration. Synthesized through the meticulous polymerization of hexamethylene diamine and sebacic acid, PA610 showcases a molecular structure that endows it with exceptional resistance to thermal degradation.

Key Attributes of Thermal Stability:

High Melting Point: PA610 has a high melting temperature, enabling it to sustain structural integrity and dimensional stability even at high temperatures. This quality is essential for applications that experience heat during processing or operational use.

Heat Resistance: This material demonstrates exceptional heat resistance, making it suitable for high-temperature environments. This attribute ensures that PA610 preserves its mechanical properties and performance in conditions where heat is consistently present.

Dimensional Stability: PA610 retains dimensional stability over a wide temperature range, minimizing the chances of warping, distortion, or shape alterations. This is especially critical in precise applications where maintaining tight tolerances is necessary.

Thermal Aging Resistance: PA610's resistance to thermal aging is notable, allowing it to endure extended exposure to high temperatures without significant degradation. This feature enhances the durability and reliability of components produced from this resin.

Uses in High-Temperature Settings:

Automotive Engine Components: PA610 is commonly employed in the automotive sector for creating engine covers, air intake systems, and other parts that endure the high temperatures produced by the engine.

Industrial Equipment Parts: Parts used in industrial machinery, such as gears, bearings, and housings, take advantage of PA610's thermal stability to ensure dependable performance in heat-generating operations.

Electrical and Electronic Equipment: PA610's capacity to withstand elevated temperatures makes it ideal for use in electrical and electronic devices. It is used in components like connectors, insulating materials, and housings where heat resistance is essential.

Oil and Gas Sector: PA610's thermal stability makes it ideal for parts in the oil and gas industry, including seals, gaskets, and other components exposed to high temperatures during processing and transport.

Nylon 6 Resin

Nylon 6 Flame Retardant

Nylon 6 Glass Fiber Reinforced

Flame Retardant Level:V-0, 5VA,f1.

UL ID:E328304/E493989.

Glass Fiber Content: 1%-40% .

Toughness, Impact Strength, Melting Point, Color and other properties can be customized.

Nylon 66 Resin

Nylon 66 Halogen-free Flame Retardant

Nylon 66 Halogen Flame Retardant

Nylon 66 Red Phosphorus Flame Retardant

Nylon 66 Glass fiber Reinforced and Toughened

Glass fiber content:20%-60%.

Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, good long-term fatigue resistance, low dielectric loss.

Nylon 610 Raw resin

Nylon 610-Halogen-free, Phosphorus-free, Flame Retardant

Nylon 610-Enhanced anti-static

Nylon 610-Glass Fiber Reinforced and Toughened

Corrosion-resistant reinforced PA610 for pipelines

Flame retardant level:V-0, 5VA.

UL ID:E328304/E493989.

Glass fiber content:30%-50%.

Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, low temperature- resistance, good long-term fatigue resistance, low dielectric loss.

Nylon 612 Raw resin

Nylon 612-Halogen-free Flame Retardant

Nylon 612-Powder Coating

Nylon 612-Reinforced for Fule Lines

Nylon 612-Carbon/Glass Fiber Reinforced

Flame retardant level:V-0, 5VA.

UL ID:E328304/E493989.

Glass fiber content:20%-60%.

Low precipitation,Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, low temperature- resistance, good long-term fatigue resistance, low dielectric loss.

Nylon 1012 Raw resin

Nylon 1012 -Reinforced for Fuel line Outer Coating

Nylon 1012-Glass Fiber Reinforced

Nylon 1012-Elastomeric

Glass fiber content:20%-60%.

Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, good long-term fatigue resistance, low dielectric loss.

Pure PA610 can usually be used as bristles/fibers for toothbrushes, monofilament, and cable core rings,

Internal coating of petroleum pipelines and cable coating.

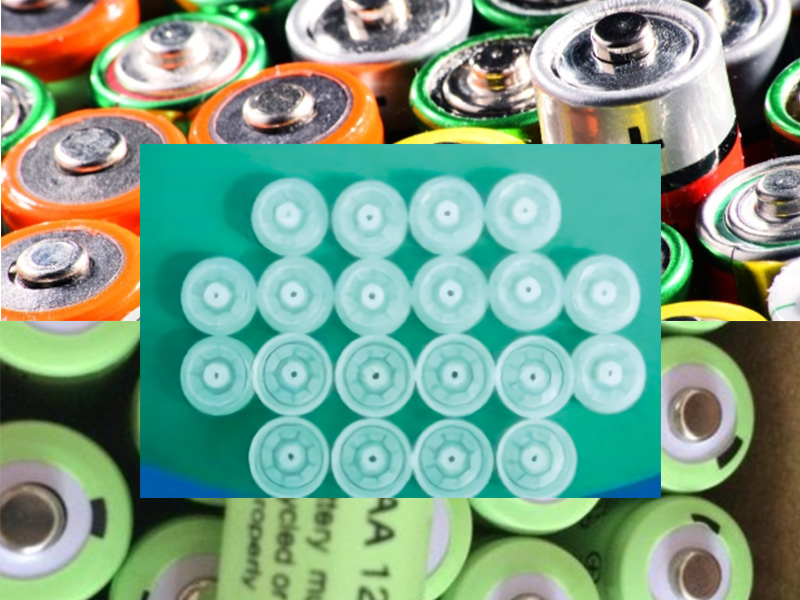

The modified PA610 can be widely used in the automotive industry, machinery manufacturing(ol containers, textile machinery parts), and in the electronicindustry for making battrey casings, instrument rails, etc. It can also be used as bristles of toothbrushes, monoflaments and cablecorerings, etc.lt can be customized in injection and extrusion grade according to customers requirements.

Automotive

Battrey

Cable

Toothbrushe

| Automotive - Engine Covers/Housings Cable Insulation and Jacketing Electrical & Electronic Plastics Electrical Encapsulation Materials Electrical Insulation Polymers Electrical Motor Insulation Electronic & Electrical Connectors High-Performance Materials for 3D Printing Innovative Furniture Design | Mobile Phone Housing & Components Oil Pan and Cylinder Head Cover Gaskets Photovoltaic Panels and Parts Plastics For Sporting Goods Polymers For Appliances Polymers for Oil and Gas Railway Technology for the Long Haul Thermoplastic Tubing and Elastomeric Hose Transformer Insulation |

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

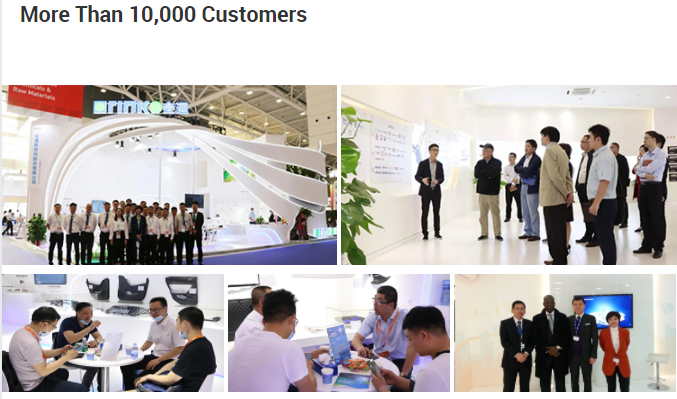

We are one of the largest listed companies in China for polymer modified materials, including polyamides, polyolefins, polystyrene, and engineering plastics. We have collaborated with multiple automotive companies, such as Volkswagen, Ford, Toyota, Honda, Audi, etc

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

Smart Factory

In the past three years, our company has invested more than 1.5 billion yuan in digitization and smart factories, and it is expected to invest more than 500 million yuan in the next three years.

•National Pilot Demonstration Project for the Integration of Manufacturing and Internet Development: manufacturing and lean quality control capabilities for modified plastics.

•Anhui Industrial Internet Enterprise Level Platform: full lifecycle control industrial Internet platform for the production of new multi-functional composite materials. •Anhui Industrial Internet New Model Application Demonstration Project: new model application demonstration project for the manufacturing and lean quality control of modified plastics.

•Hefei Top Ten Industrial Empowerment Scenarios Demonstration Project: Demonstration of digital collaborative industrial internet in the high-performance fireproof material industry chain.

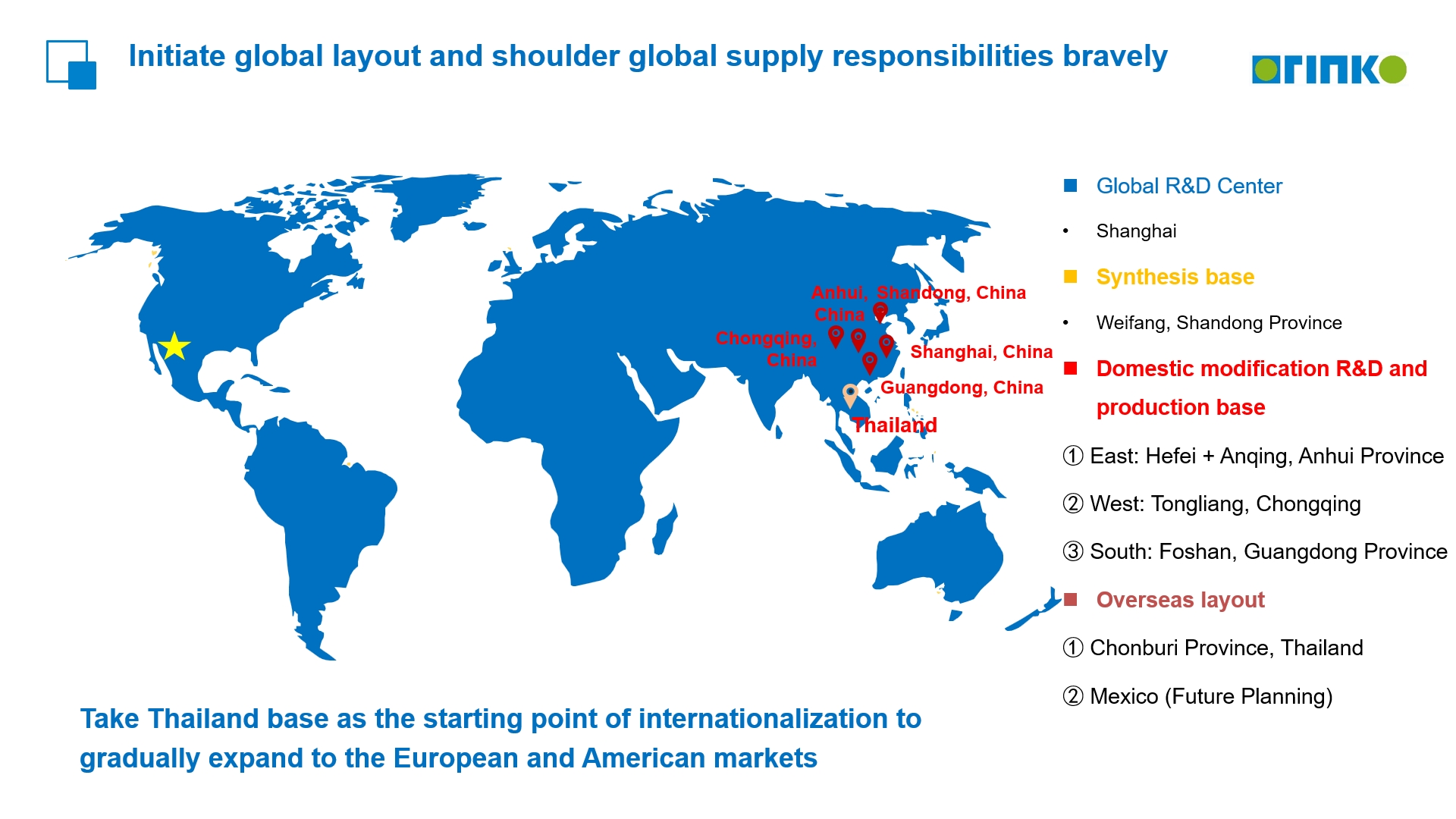

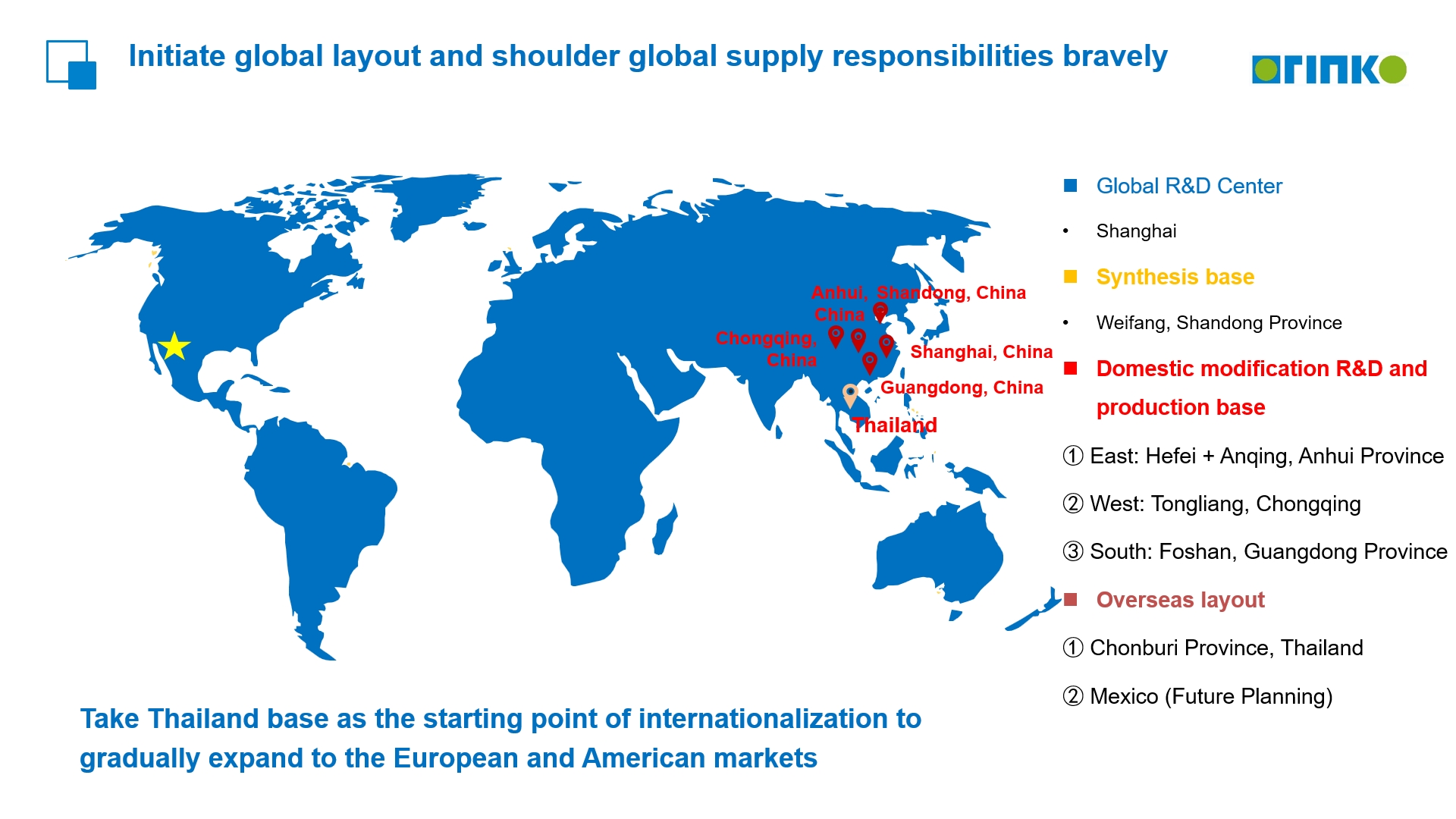

Initiate global layout and shoulder global supply responsibilities bravely

Global R&D Center

•Shanghai

Synthesis base

•Weifang, Shandong Province

Domestic modification R&D and production base

① East: Hefei + Anqing, Anhui Province

② West: Tongliang, Chongqing

③ South: Foshan, Guangdong Province

Overseas layout

① Chonburi Province, Thailand

② Mexico (Future Planning)

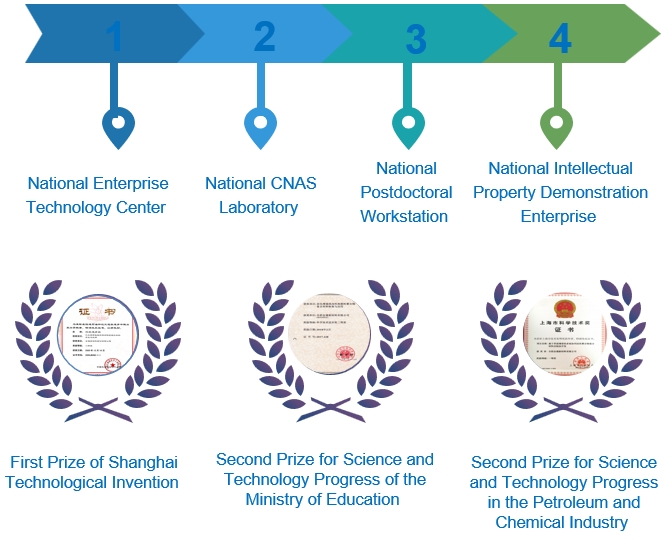

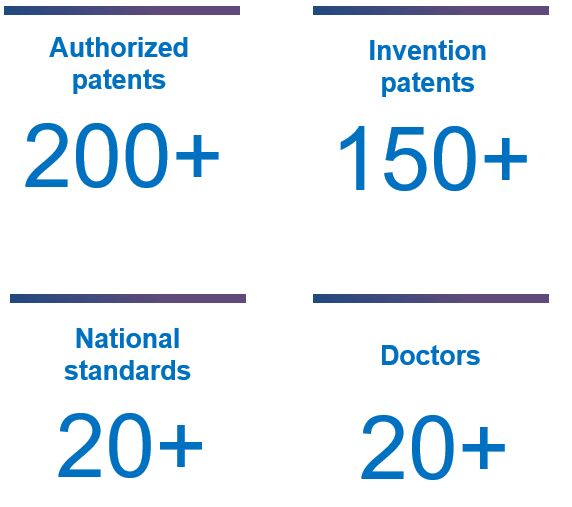

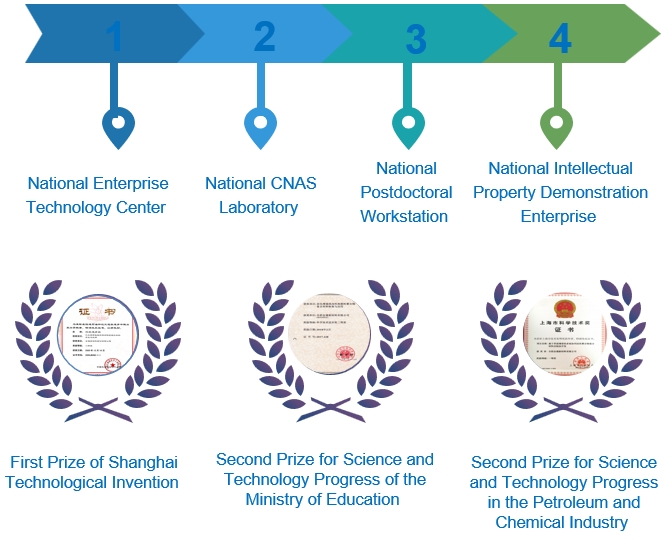

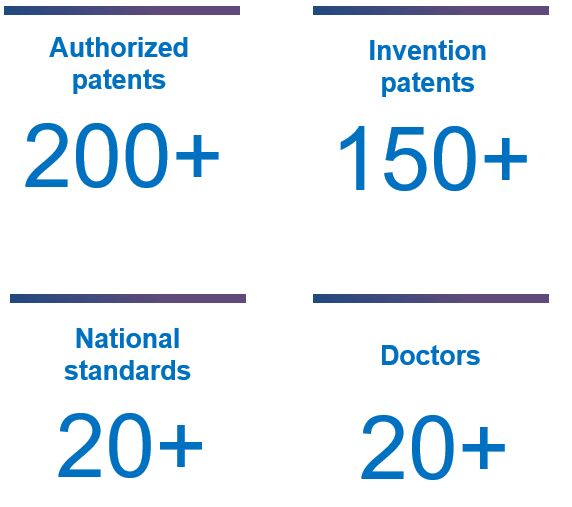

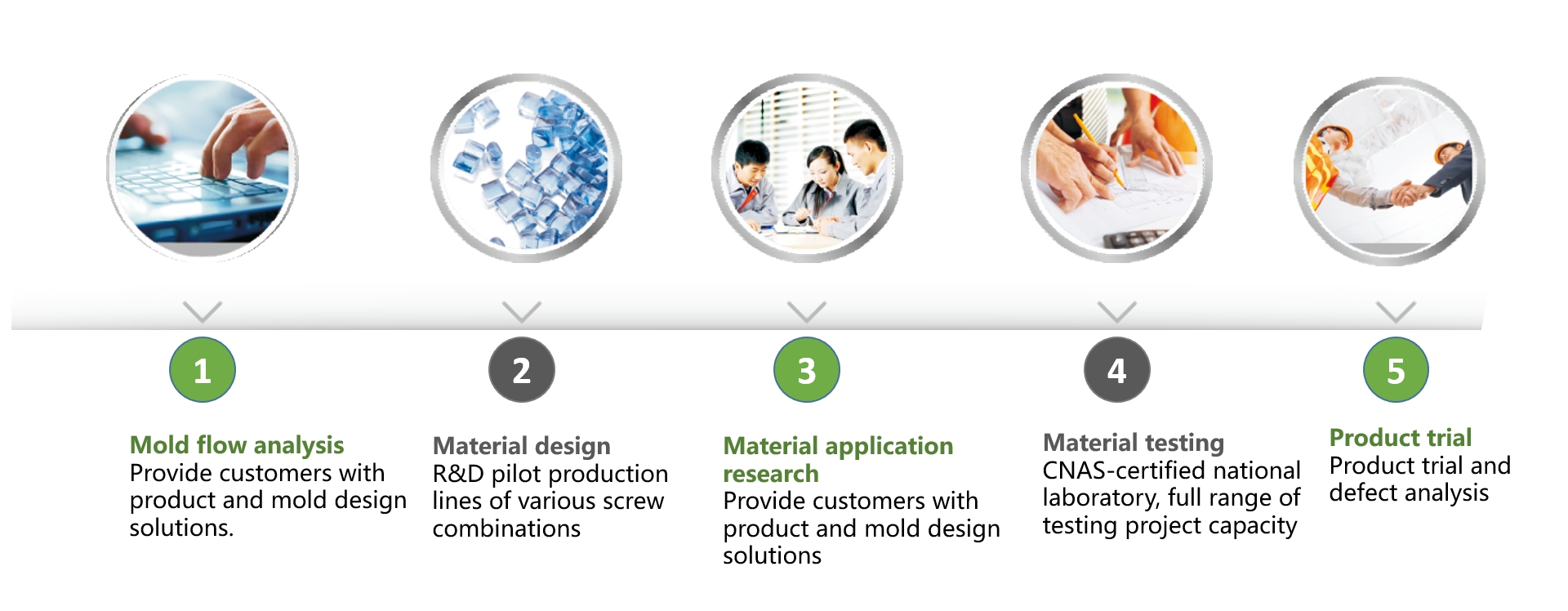

Inject impetus into the enterprise and industrial development with continuous innovation investment

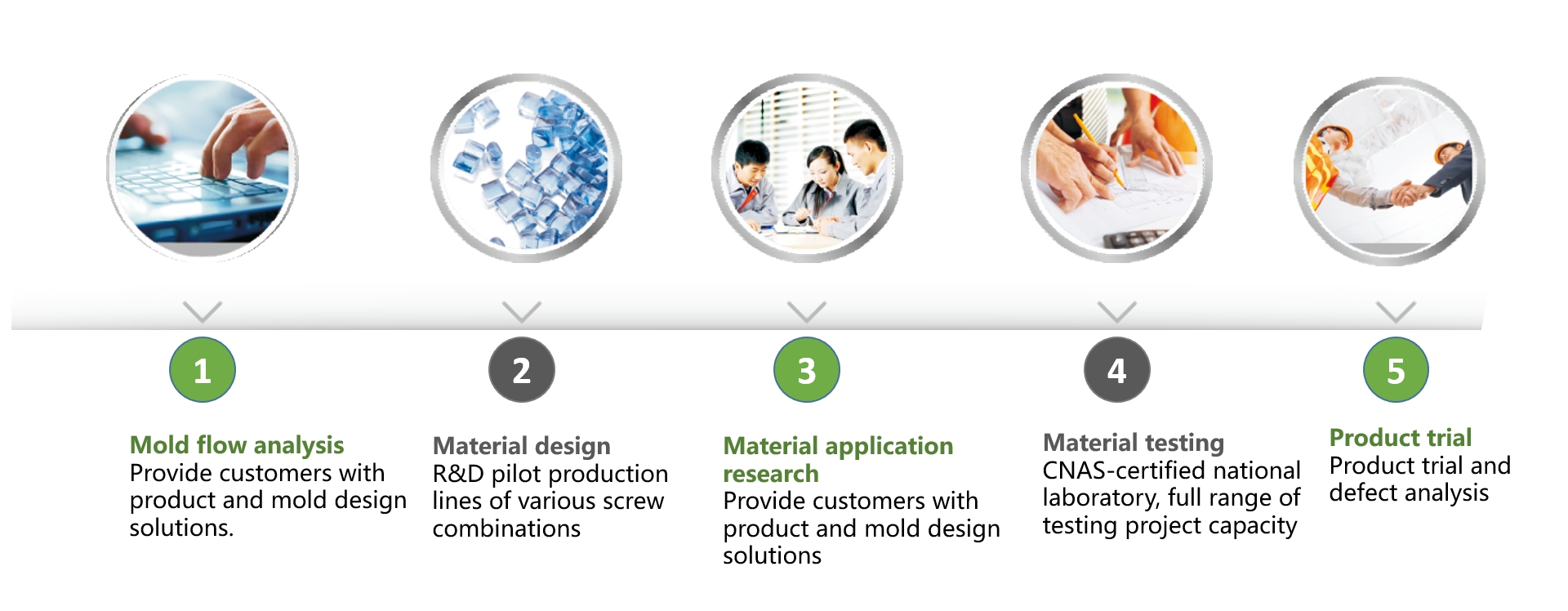

Innovation capability-provide overall solutions

Start from home appliances, serve many industry leaders and become their strategic partners

ORINKO Polyamide 610 (PA610)

is a long-chain nylon, which is made by condensation polymerization of ethylenediamine and dodecanedioic acid as raw materials. The raw material dodecanedioic acid can be produced through chemical synthesis or microbial fermentation. ORINKO integrates PA610 forward and backward, with our own factories in backward raw material production, forward resin polymerization and polyamide compound.

Polyamide 610 Resin: Unrivaled Thermal Stability

Polyamide 610 (PA610) resin stands as a testament to superior thermal stability, making it a standout choice among thermoplastics for applications where exposure to elevated temperatures is a critical consideration. Synthesized through the meticulous polymerization of hexamethylene diamine and sebacic acid, PA610 showcases a molecular structure that endows it with exceptional resistance to thermal degradation.

Key Attributes of Thermal Stability:

High Melting Point: PA610 has a high melting temperature, enabling it to sustain structural integrity and dimensional stability even at high temperatures. This quality is essential for applications that experience heat during processing or operational use.

Heat Resistance: This material demonstrates exceptional heat resistance, making it suitable for high-temperature environments. This attribute ensures that PA610 preserves its mechanical properties and performance in conditions where heat is consistently present.

Dimensional Stability: PA610 retains dimensional stability over a wide temperature range, minimizing the chances of warping, distortion, or shape alterations. This is especially critical in precise applications where maintaining tight tolerances is necessary.

Thermal Aging Resistance: PA610's resistance to thermal aging is notable, allowing it to endure extended exposure to high temperatures without significant degradation. This feature enhances the durability and reliability of components produced from this resin.

Uses in High-Temperature Settings:

Automotive Engine Components: PA610 is commonly employed in the automotive sector for creating engine covers, air intake systems, and other parts that endure the high temperatures produced by the engine.

Industrial Equipment Parts: Parts used in industrial machinery, such as gears, bearings, and housings, take advantage of PA610's thermal stability to ensure dependable performance in heat-generating operations.

Electrical and Electronic Equipment: PA610's capacity to withstand elevated temperatures makes it ideal for use in electrical and electronic devices. It is used in components like connectors, insulating materials, and housings where heat resistance is essential.

Oil and Gas Sector: PA610's thermal stability makes it ideal for parts in the oil and gas industry, including seals, gaskets, and other components exposed to high temperatures during processing and transport.

Nylon 6 Resin

Nylon 6 Flame Retardant

Nylon 6 Glass Fiber Reinforced

Flame Retardant Level:V-0, 5VA,f1.

UL ID:E328304/E493989.

Glass Fiber Content: 1%-40% .

Toughness, Impact Strength, Melting Point, Color and other properties can be customized.

Nylon 66 Resin

Nylon 66 Halogen-free Flame Retardant

Nylon 66 Halogen Flame Retardant

Nylon 66 Red Phosphorus Flame Retardant

Nylon 66 Glass fiber Reinforced and Toughened

Glass fiber content:20%-60%.

Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, good long-term fatigue resistance, low dielectric loss.

Nylon 610 Raw resin

Nylon 610-Halogen-free, Phosphorus-free, Flame Retardant

Nylon 610-Enhanced anti-static

Nylon 610-Glass Fiber Reinforced and Toughened

Corrosion-resistant reinforced PA610 for pipelines

Flame retardant level:V-0, 5VA.

UL ID:E328304/E493989.

Glass fiber content:30%-50%.

Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, low temperature- resistance, good long-term fatigue resistance, low dielectric loss.

Nylon 612 Raw resin

Nylon 612-Halogen-free Flame Retardant

Nylon 612-Powder Coating

Nylon 612-Reinforced for Fule Lines

Nylon 612-Carbon/Glass Fiber Reinforced

Flame retardant level:V-0, 5VA.

UL ID:E328304/E493989.

Glass fiber content:20%-60%.

Low precipitation,Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, low temperature- resistance, good long-term fatigue resistance, low dielectric loss.

Nylon 1012 Raw resin

Nylon 1012 -Reinforced for Fuel line Outer Coating

Nylon 1012-Glass Fiber Reinforced

Nylon 1012-Elastomeric

Glass fiber content:20%-60%.

Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, good long-term fatigue resistance, low dielectric loss.

Pure PA610 can usually be used as bristles/fibers for toothbrushes, monofilament, and cable core rings,

Internal coating of petroleum pipelines and cable coating.

The modified PA610 can be widely used in the automotive industry, machinery manufacturing(ol containers, textile machinery parts), and in the electronicindustry for making battrey casings, instrument rails, etc. It can also be used as bristles of toothbrushes, monoflaments and cablecorerings, etc.lt can be customized in injection and extrusion grade according to customers requirements.

Automotive

Battrey

Cable

Toothbrushe

| Automotive - Engine Covers/Housings Cable Insulation and Jacketing Electrical & Electronic Plastics Electrical Encapsulation Materials Electrical Insulation Polymers Electrical Motor Insulation Electronic & Electrical Connectors High-Performance Materials for 3D Printing Innovative Furniture Design | Mobile Phone Housing & Components Oil Pan and Cylinder Head Cover Gaskets Photovoltaic Panels and Parts Plastics For Sporting Goods Polymers For Appliances Polymers for Oil and Gas Railway Technology for the Long Haul Thermoplastic Tubing and Elastomeric Hose Transformer Insulation |

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

We are one of the largest listed companies in China for polymer modified materials, including polyamides, polyolefins, polystyrene, and engineering plastics. We have collaborated with multiple automotive companies, such as Volkswagen, Ford, Toyota, Honda, Audi, etc

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

Smart Factory

In the past three years, our company has invested more than 1.5 billion yuan in digitization and smart factories, and it is expected to invest more than 500 million yuan in the next three years.

•National Pilot Demonstration Project for the Integration of Manufacturing and Internet Development: manufacturing and lean quality control capabilities for modified plastics.

•Anhui Industrial Internet Enterprise Level Platform: full lifecycle control industrial Internet platform for the production of new multi-functional composite materials. •Anhui Industrial Internet New Model Application Demonstration Project: new model application demonstration project for the manufacturing and lean quality control of modified plastics.

•Hefei Top Ten Industrial Empowerment Scenarios Demonstration Project: Demonstration of digital collaborative industrial internet in the high-performance fireproof material industry chain.

Initiate global layout and shoulder global supply responsibilities bravely

Global R&D Center

•Shanghai

Synthesis base

•Weifang, Shandong Province

Domestic modification R&D and production base

① East: Hefei + Anqing, Anhui Province

② West: Tongliang, Chongqing

③ South: Foshan, Guangdong Province

Overseas layout

① Chonburi Province, Thailand

② Mexico (Future Planning)

Inject impetus into the enterprise and industrial development with continuous innovation investment

Innovation capability-provide overall solutions

Start from home appliances, serve many industry leaders and become their strategic partners

No.2 Luhua Road,Boyan Science Park,Hefei,Anhui Province,China