Tel/Whatsapp:+86-13013179882 Email:futao@orinkoplastic.com

| Availability: | |

|---|---|

| Quantity: | |

PA612

Orinko

ORINKO Polyamide 612 (PA612) The long-chain nylon is crafted through condensation polymerization, utilizing ethylenediamine and dodecanedioic acid as its foundational components.

Depending on formulation and viscosity, ORINKO Polyamide PA612 can be processed using a range of different methods, such as injection molding, tube extrusion, film extrusion or blow molding. By using additives, fillers, pigments, plasticizers, modifiers or processing aids. ORINKO can precisely adjust Polyamide to customer requirements and specific applications.

ORINKO Polyamide PA612 resin has a series of excellent properties, such as:

Nylon 610 Raw resin

Nylon 610-Halogen-free, Phosphorus-free, Flame Retardant

Nylon 610-Enhanced anti-static

Nylon 610-Glass Fiber Reinforced and Toughened

Corrosion-resistant reinforced PA610 for pipelines

Flame retardant level:V-0, 5VA.

UL ID:E328304/E493989.

Glass fiber content:30%-50%.

Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, low temperature- resistance, good long-term fatigue resistance, low dielectric loss.

Nylon 612 Raw resin

Nylon 612-Halogen-free Flame Retardant

Nylon 612-Powder Coating

Nylon 612-Reinforced for Fule Lines

Nylon 612-Carbon/Glass Fiber Reinforced

Flame retardant level:V-0, 5VA.

UL ID:E328304/E493989.

Glass fiber content:20%-60%.

Low precipitation,Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, low temperature- resistance, good long-term fatigue resistance, low dielectric loss.

Nylon 1012 Raw resin

Nylon 1012 -Reinforced for Fuel line Outer Coating

Nylon 1012-Glass Fiber Reinforced

Nylon 1012-Elastomeric

Glass fiber content:20%-60%.

Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, good long-term fatigue resistance, low dielectric loss.

Pure PA612 can usually be used as bristles/fibers for toothbrushes, monofilament, and cable core rings,

Internal coating of petroleum pipelines and cable coating.

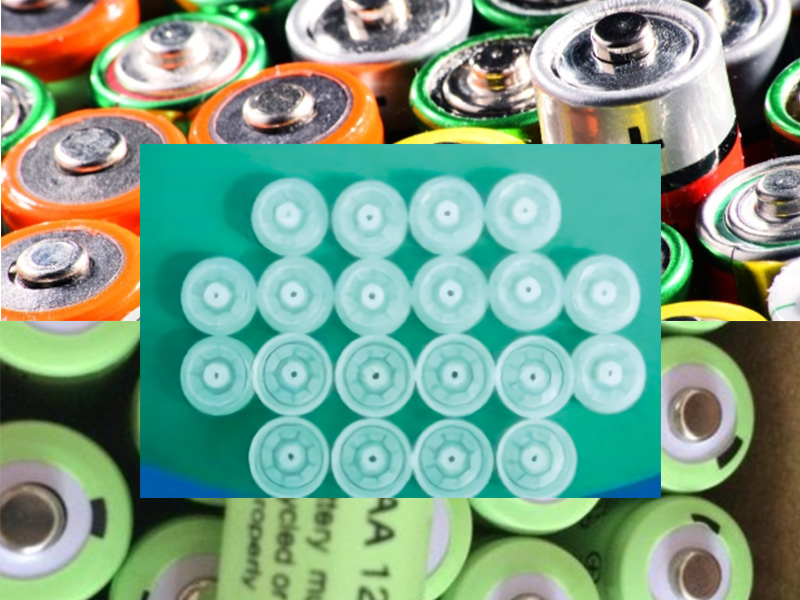

The modified PA612 can be widely used in the automotive industry, machinery manufacturing(ol containers, textile machinery parts), and in the electronicindustry for making battrey casings, instrument rails, etc. Additionally, it finds application as the bristles in toothbrushes, monofilaments, and cable cores, among other uses. This material can be tailored to meet customers' specific needs, be it in injection molding grade or extrusion grade.

Automotive

Battery

Cable

Toothbrushe

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

contact us

WP: +8613013179882

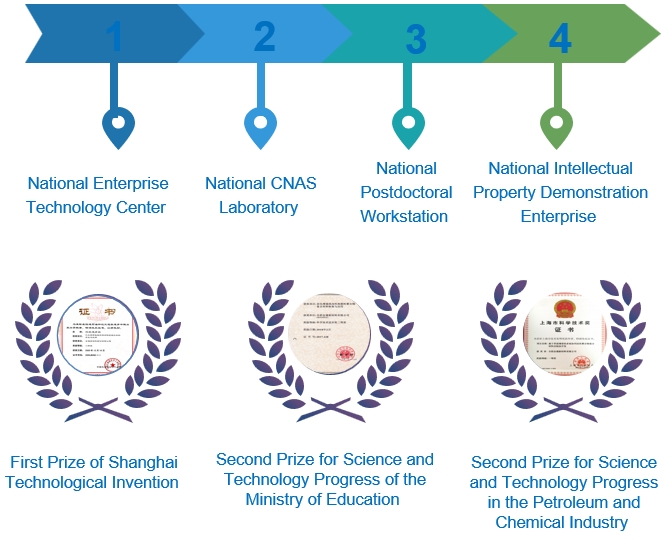

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

Smart Factory

•National Pilot Demonstration Project for the Integration of Manufacturing and Internet Development: manufacturing and lean quality control capabilities for modified plastics.

•Anhui Industrial Internet Enterprise Level Platform: full lifecycle control industrial Internet platform for the production of new multi-functional composite materials.

•Hefei Top Ten Industrial Empowerment Scenarios Demonstration Project: Demonstration of digital collaborative industrial internet in the high-performance fireproof material industry chain.

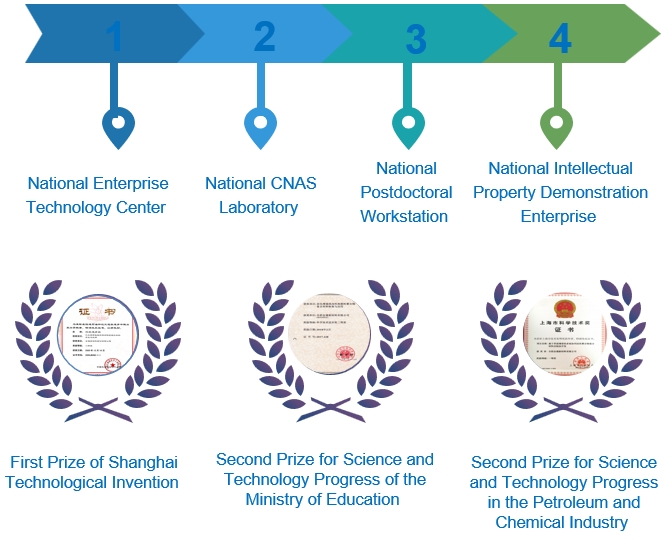

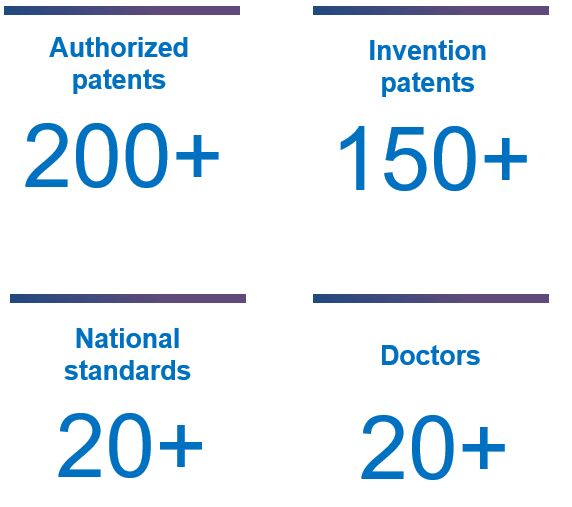

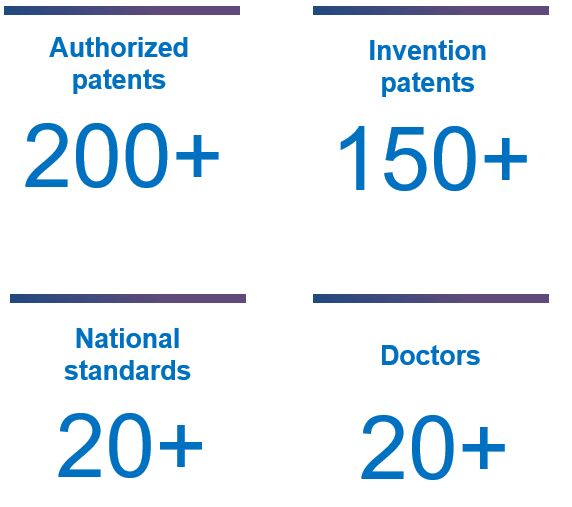

Inject impetus into the enterprise and industrial development with continuous innovation investment

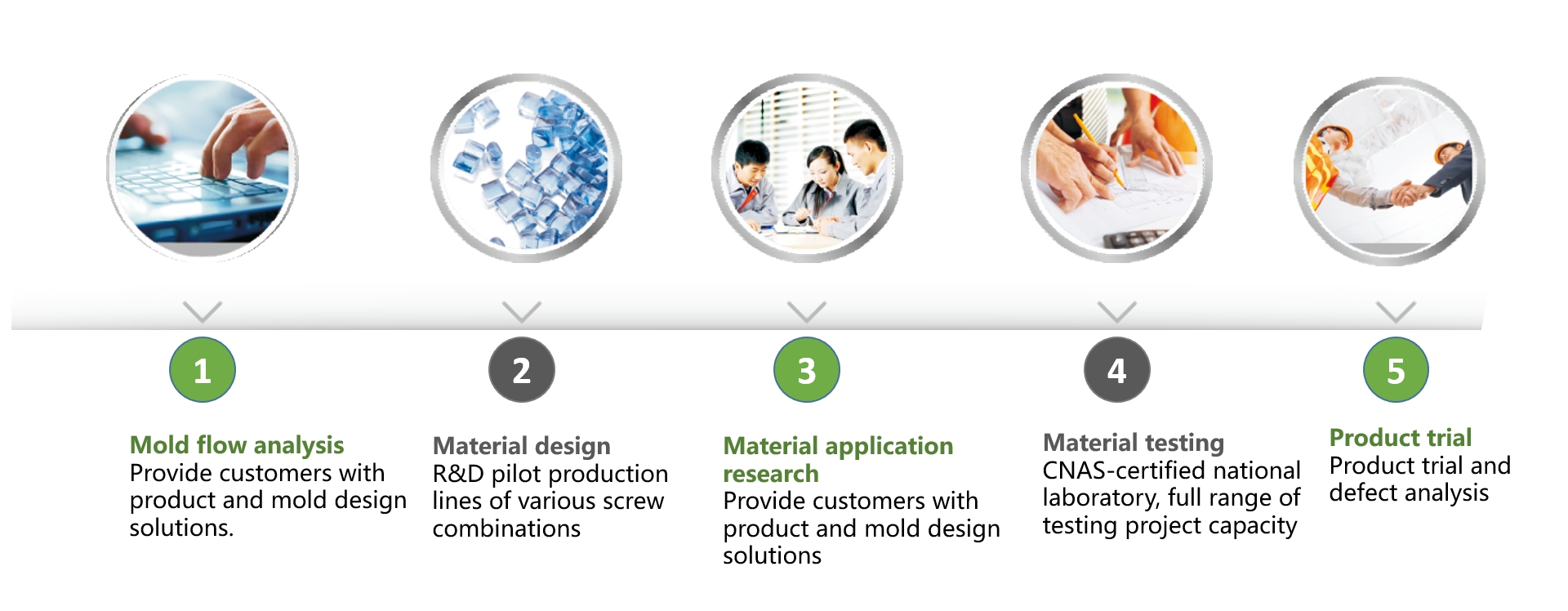

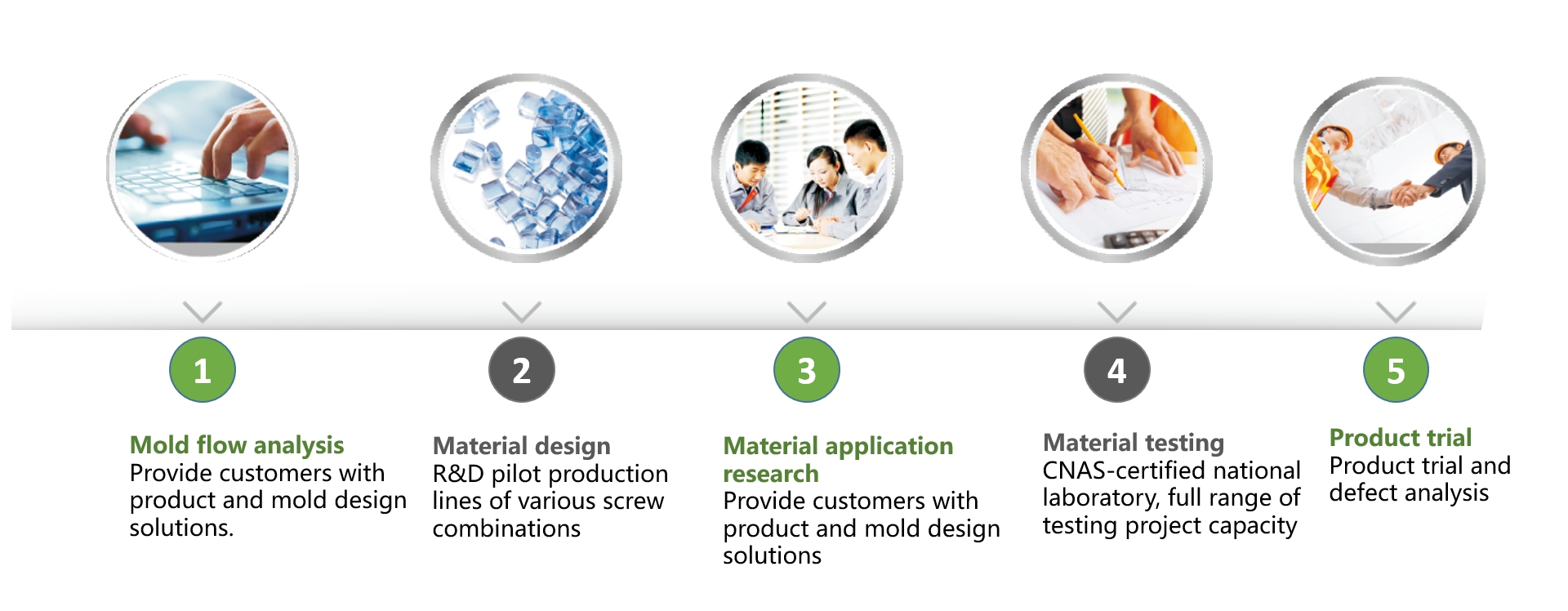

Innovation capability-provide overall solutions

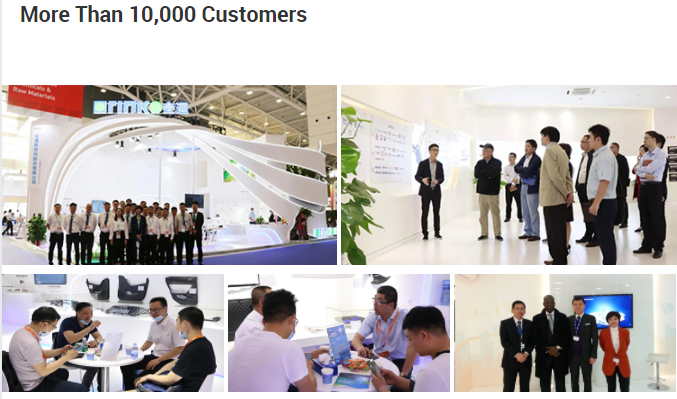

Start from home appliances, serve many industry leaders and become their strategic partners

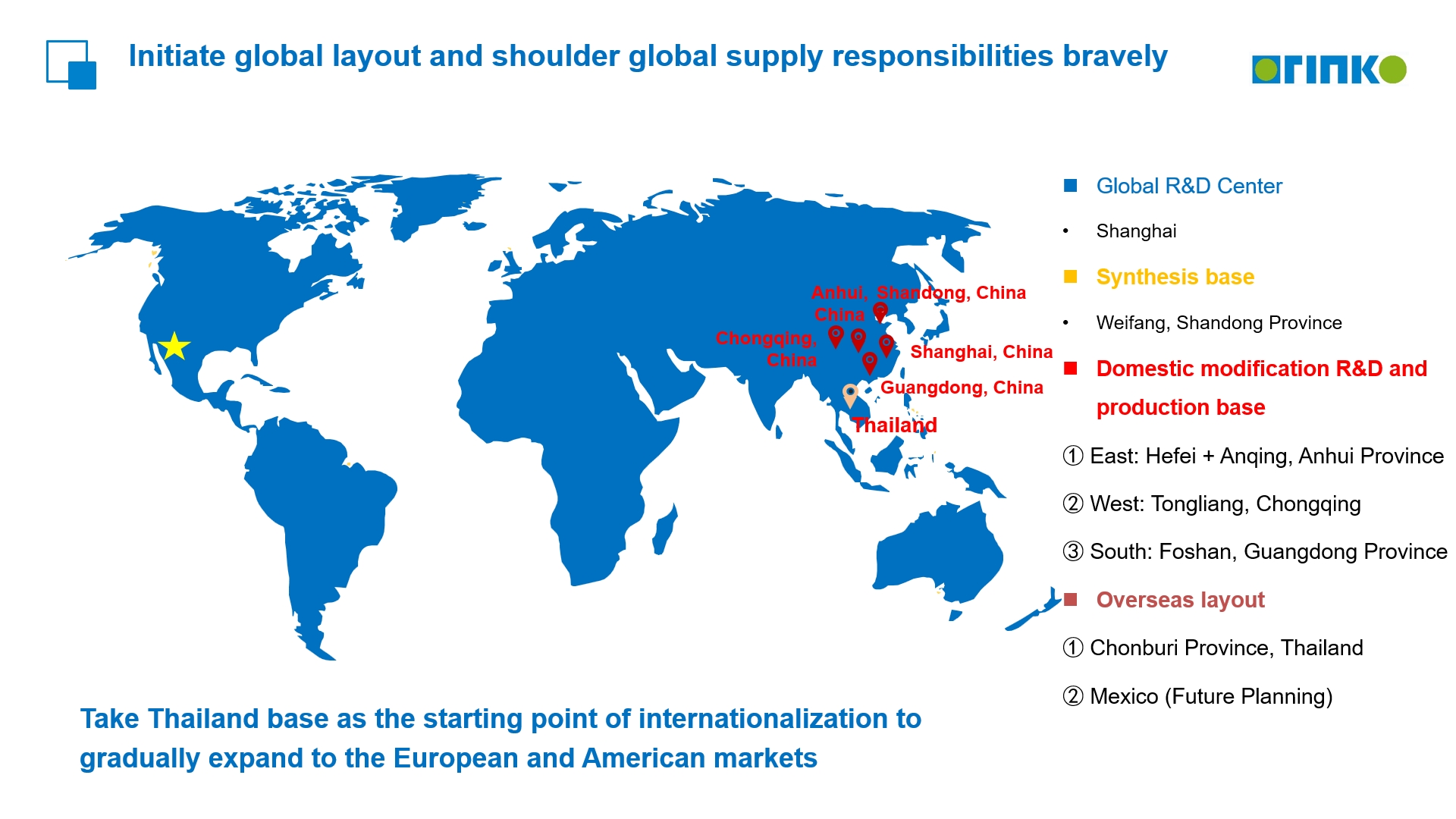

Orinko Advanced Materials Co., Ltd. primarily dedicates itself to the research, development, production, and distribution of high-molecular modified materials, striving to offer its customers comprehensive material solutions that excel in both performance and functionality.

Known for its stellar reputation, relentless innovation, consistent quality, and cutting-edge services, Orink provides its customers with superior products and services, ultimately contributing to a greener and more sustainable lifestyle for all.

ORINKO Polyamide 612 (PA612) The long-chain nylon is crafted through condensation polymerization, utilizing ethylenediamine and dodecanedioic acid as its foundational components.

Depending on formulation and viscosity, ORINKO Polyamide PA612 can be processed using a range of different methods, such as injection molding, tube extrusion, film extrusion or blow molding. By using additives, fillers, pigments, plasticizers, modifiers or processing aids. ORINKO can precisely adjust Polyamide to customer requirements and specific applications.

ORINKO Polyamide PA612 resin has a series of excellent properties, such as:

Nylon 610 Raw resin

Nylon 610-Halogen-free, Phosphorus-free, Flame Retardant

Nylon 610-Enhanced anti-static

Nylon 610-Glass Fiber Reinforced and Toughened

Corrosion-resistant reinforced PA610 for pipelines

Flame retardant level:V-0, 5VA.

UL ID:E328304/E493989.

Glass fiber content:30%-50%.

Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, low temperature- resistance, good long-term fatigue resistance, low dielectric loss.

Nylon 612 Raw resin

Nylon 612-Halogen-free Flame Retardant

Nylon 612-Powder Coating

Nylon 612-Reinforced for Fule Lines

Nylon 612-Carbon/Glass Fiber Reinforced

Flame retardant level:V-0, 5VA.

UL ID:E328304/E493989.

Glass fiber content:20%-60%.

Low precipitation,Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, low temperature- resistance, good long-term fatigue resistance, low dielectric loss.

Nylon 1012 Raw resin

Nylon 1012 -Reinforced for Fuel line Outer Coating

Nylon 1012-Glass Fiber Reinforced

Nylon 1012-Elastomeric

Glass fiber content:20%-60%.

Anti-static, Coolant-resistance, hydrolysis-resistance, chemical-resistance, salt corrosion- resistance, good long-term fatigue resistance, low dielectric loss.

Pure PA612 can usually be used as bristles/fibers for toothbrushes, monofilament, and cable core rings,

Internal coating of petroleum pipelines and cable coating.

The modified PA612 can be widely used in the automotive industry, machinery manufacturing(ol containers, textile machinery parts), and in the electronicindustry for making battrey casings, instrument rails, etc. Additionally, it finds application as the bristles in toothbrushes, monofilaments, and cable cores, among other uses. This material can be tailored to meet customers' specific needs, be it in injection molding grade or extrusion grade.

Automotive

Battery

Cable

Toothbrushe

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

contact us

WP: +8613013179882

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

Smart Factory

•National Pilot Demonstration Project for the Integration of Manufacturing and Internet Development: manufacturing and lean quality control capabilities for modified plastics.

•Anhui Industrial Internet Enterprise Level Platform: full lifecycle control industrial Internet platform for the production of new multi-functional composite materials.

•Hefei Top Ten Industrial Empowerment Scenarios Demonstration Project: Demonstration of digital collaborative industrial internet in the high-performance fireproof material industry chain.

Inject impetus into the enterprise and industrial development with continuous innovation investment

Innovation capability-provide overall solutions

Start from home appliances, serve many industry leaders and become their strategic partners

Orinko Advanced Materials Co., Ltd. primarily dedicates itself to the research, development, production, and distribution of high-molecular modified materials, striving to offer its customers comprehensive material solutions that excel in both performance and functionality.

Known for its stellar reputation, relentless innovation, consistent quality, and cutting-edge services, Orink provides its customers with superior products and services, ultimately contributing to a greener and more sustainable lifestyle for all.

No.2 Luhua Road,Boyan Science Park,Hefei,Anhui Province,China