Tel/Whatsapp: +86-13013179882 Email: futao@orinkoplastic.com

| Availability: | |

|---|---|

| Quantity: | |

PA610

Orinko

ORINKO Polyamide 610 (PA610)

is a long-chain nylon, which is made by condensation polymerization of ethylenediamine and dodecanedioic acid as raw materials. The raw material dodecanedioic acid can be produced through chemical synthesis or microbial fermentation. ORINKO integrates PA610 forward and backward, with our own factories in backward raw material production, forward resin polymerization and polyamide compound.

Polyamide 610 Resin: Unrivaled Thermal Stability

Polyamide 610 (PA610) resin stands out for its exceptional thermal stability, making it an ideal choice among thermoplastics for applications that involve exposure to high temperatures. This resin is produced through the precise polymerization of hexamethylene diamine and sebacic acid, creating a molecular structure that offers outstanding resistance to thermal degradation.

Applications in High-Temperature Environments:

Automotive Under-the-Hood Components: PA610 is commonly used in the automotive industry for creating under-the-hood parts such as engine covers, air intake systems, and other components that must withstand the

high temperatures generated by the engine.

Industrial Machinery Parts: In industrial machinery, PA610 is utilized for manufacturing gears, bearings, and housings. Its thermal stability ensures reliable performance in applications where heat is produced during operation.

Our Nylon/Polyamide Types

Nylon 612 Raw resin

Nylon 612-Halogen-free Flame Retardant

Nylon 612-Powder Coating

Nylon 612-Reinforced for Fule Lines

Nylon 612-Carbon/Glass Fiber Reinforced

Nylon 1012 Raw resin

Nylon 1012 -Reinforced for Fuel line Outer Coating

Nylon 1012-Glass Fiber Reinforced

Nylon 1012-Elastomeric

Pure PA610 is commonly used for toothbrush bristles, monofilaments, and cable core rings. It is also utilized as an internal coating for petroleum pipelines and as a coating for cables.

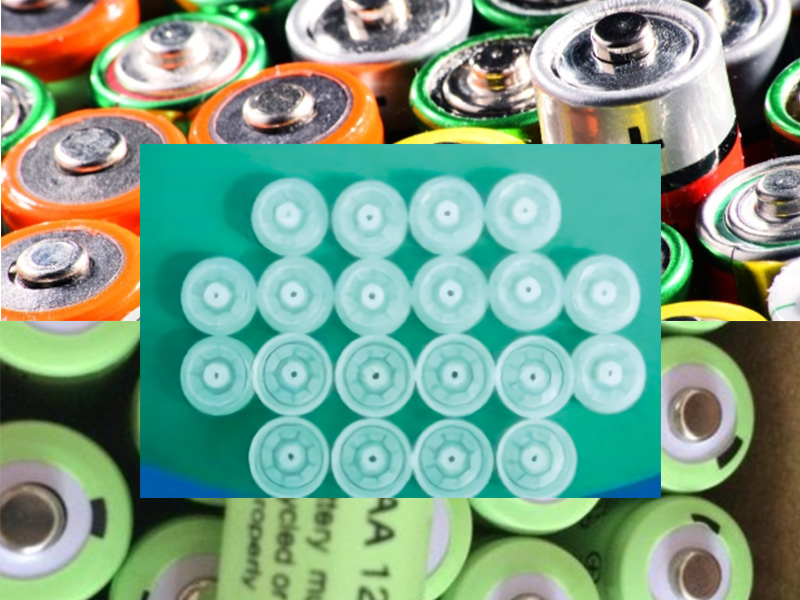

The modified PA610 can be widely used in the automotive industry, machinery manufacturing(ol containers, textile machinery parts), and in the electronicindustry for making battrey casings, instrument rails, etc. It can also be used as bristles of toothbrushes, monoflaments and cablecorerings, etc.lt can be customized in injection and extrusion grade according to customers requirements.

Automotive

Battery

Cable

Toothbrushe

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

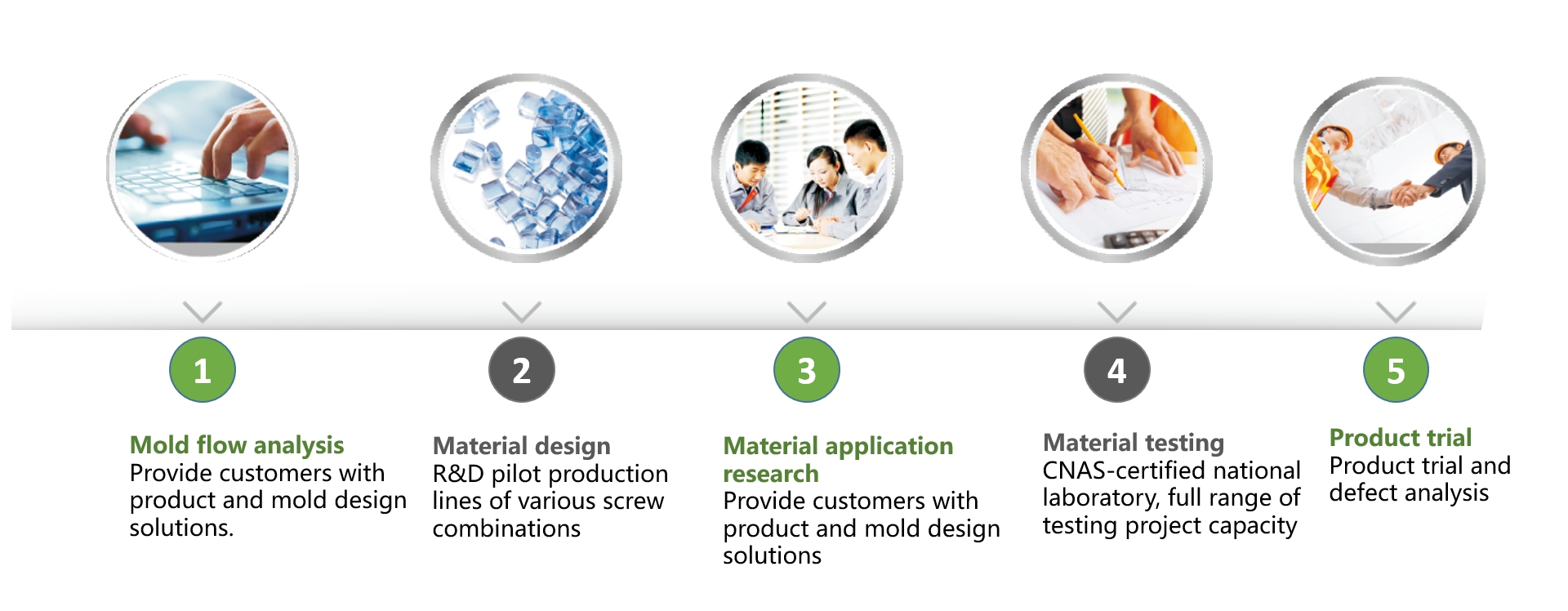

As a full service provider Orinko

will give you all the necessary technical support

and marketing advice to enable you to process

and sell your products successfully.

Get in touch with us to find the perfect solution for your application.

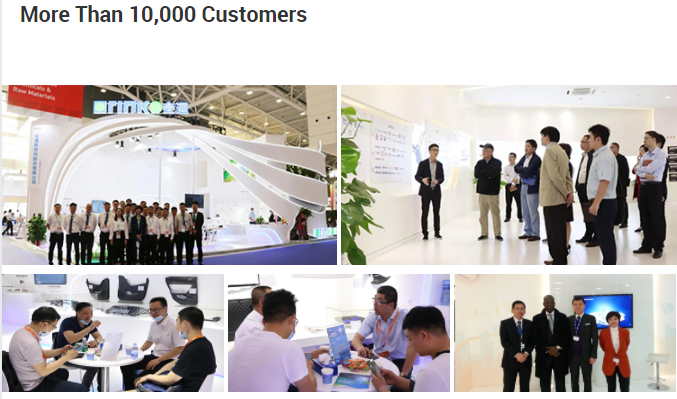

As a premier publicly listed enterprise in China, we specialize in polymer-enhanced materials like polyamides, polyolefins, polystyrene, and advanced engineering plastics. Our portfolio boasts collaborations with numerous automotive giants, spanning Volkswagen, Ford, Toyota, Honda, Audi, and several other renowned manufacturers.

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

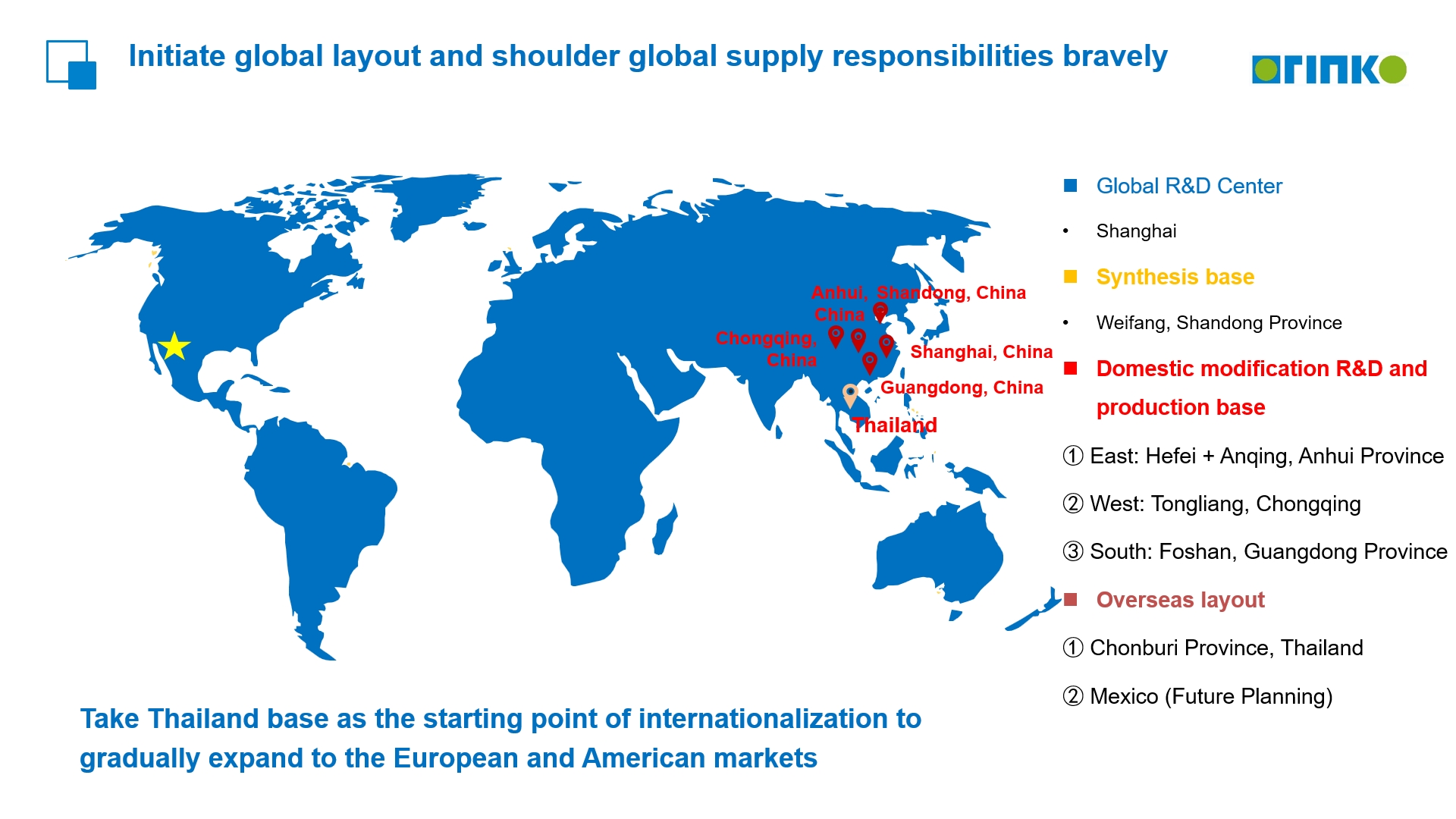

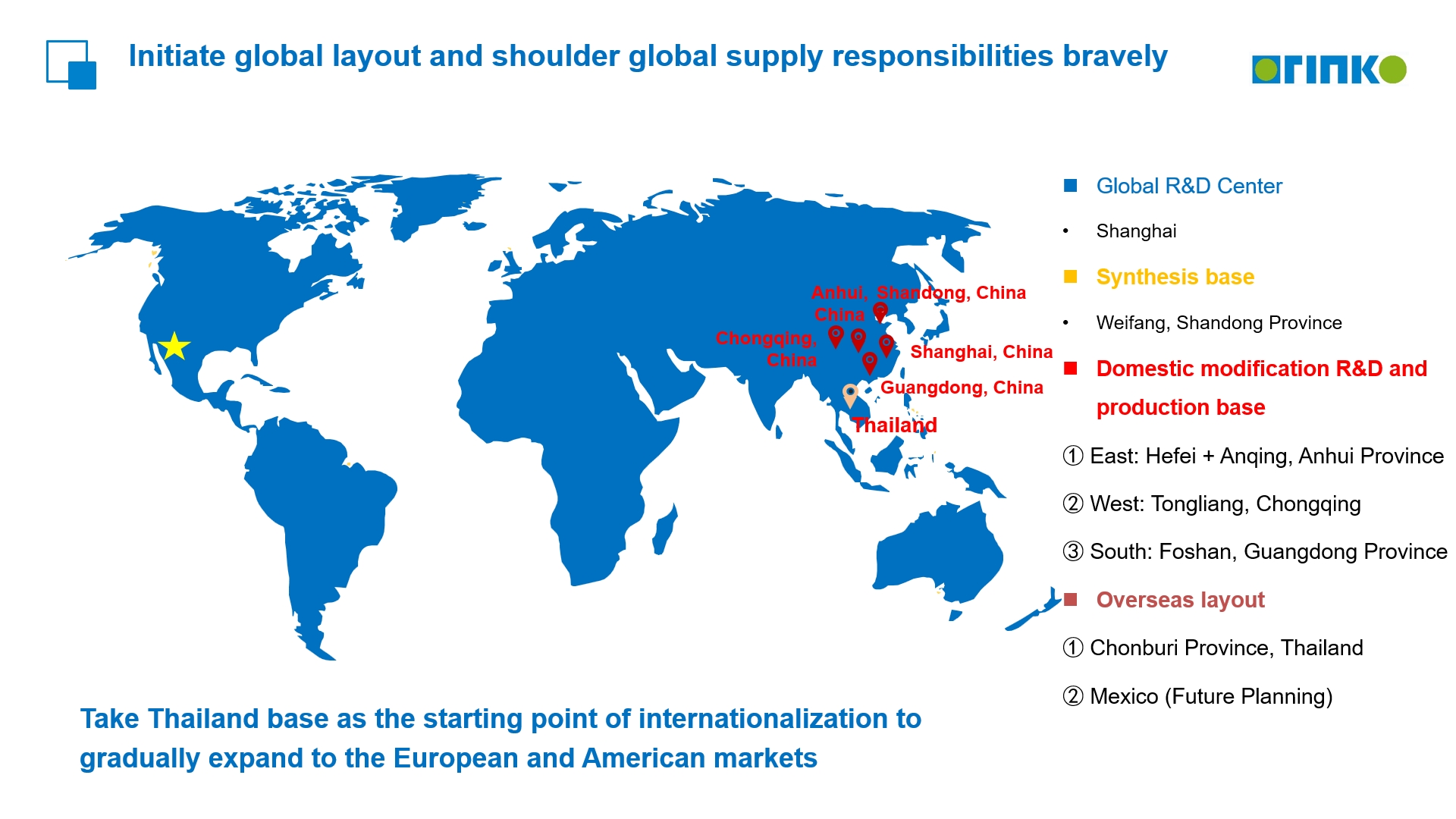

Initiate global layout and shoulder global supply responsibilities bravely

Global R&D Center

•Shanghai

Synthesis base

•Weifang, Shandong Province

Domestic modification R&D and production base

① East: Hefei + Anqing, Anhui Province

② West: Tongliang, Chongqing

③ South: Foshan, Guangdong Province

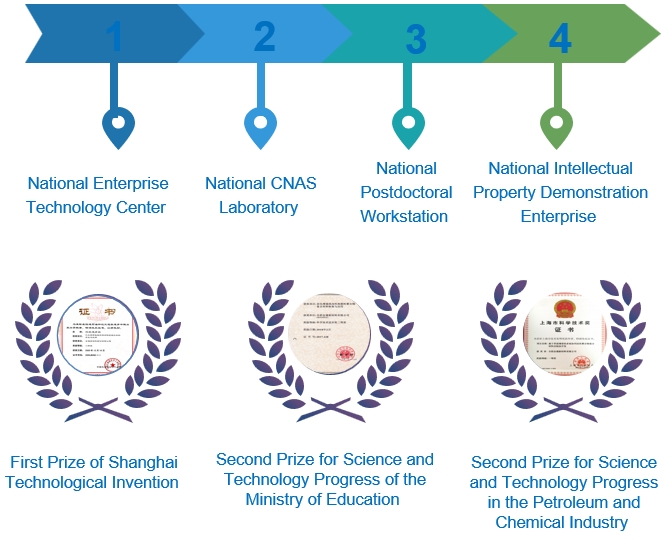

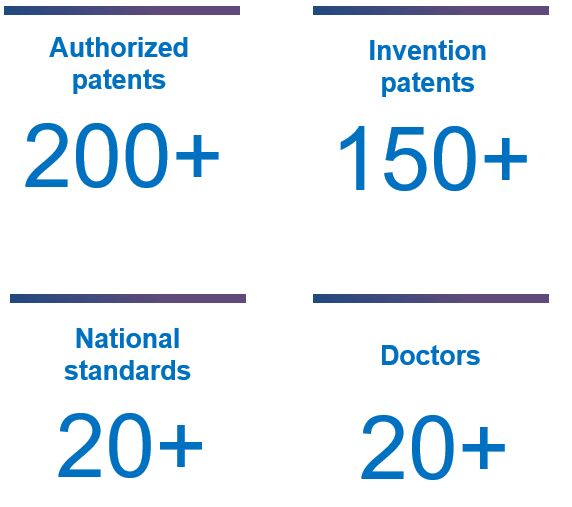

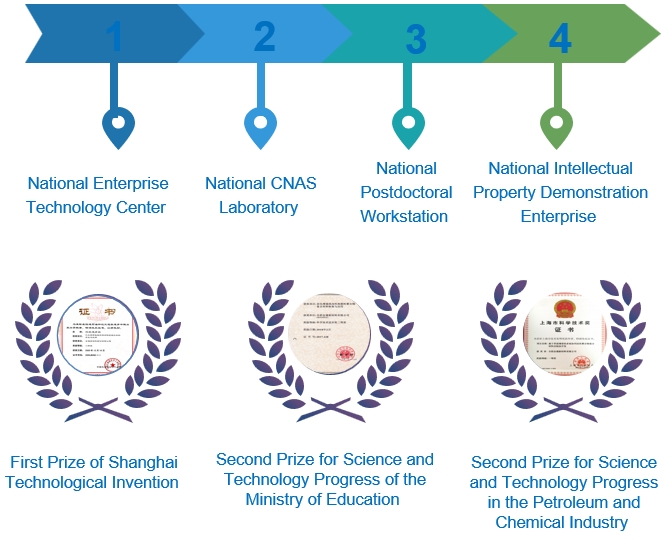

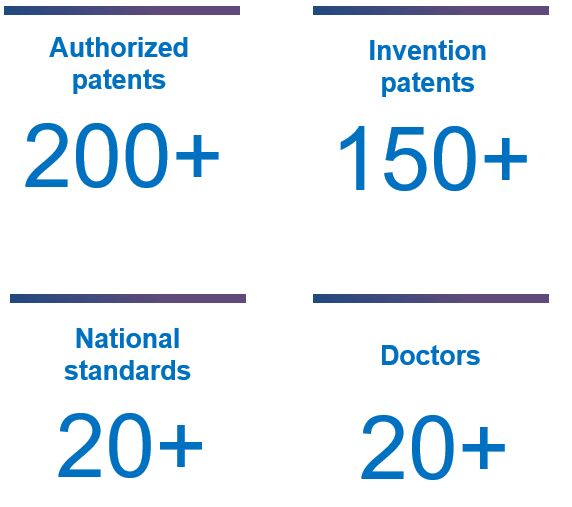

Inject impetus into the enterprise and industrial development with continuous innovation investment

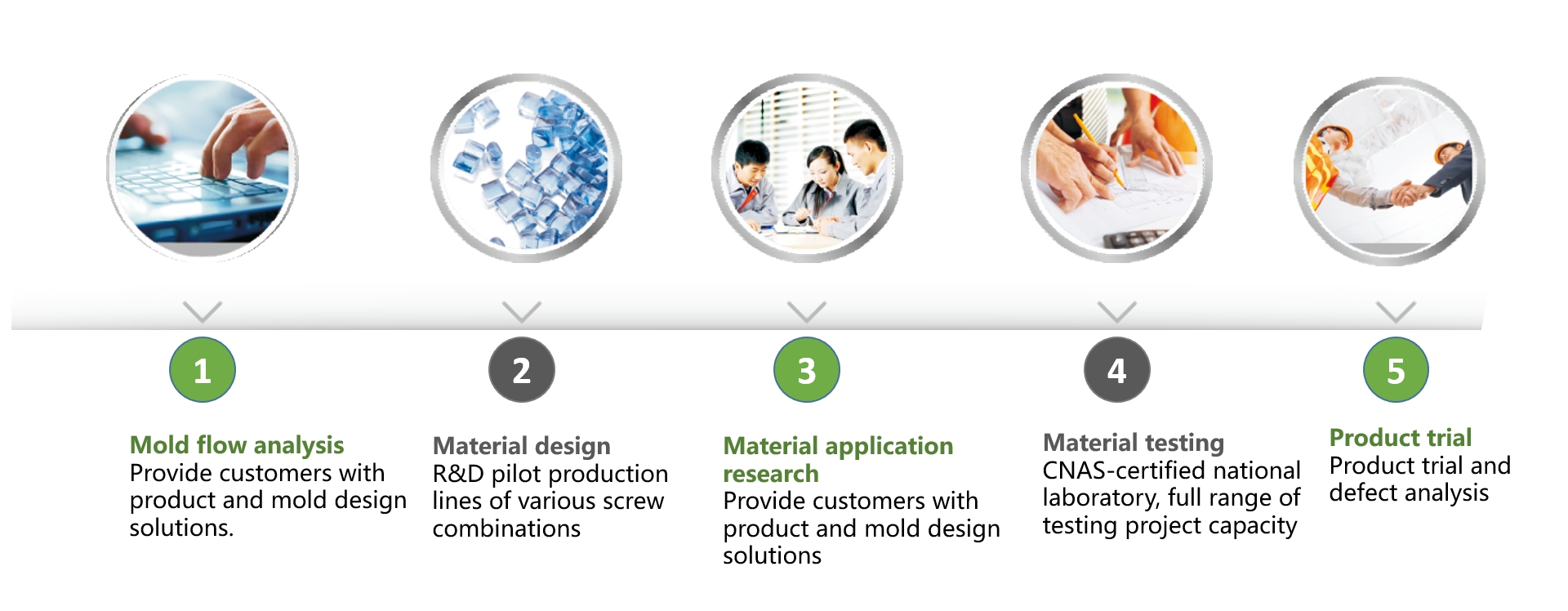

Innovation capability-provide overall solutions

Start from home appliances, serve many industry leaders and become their strategic partners

With decades of experience in the industry, Orink has established itself as a leader in the modified materials sector. We are one of the largest and most widely recognized enterprises in China, known for our extensive range of high-molecular modified materials. Our product portfolio includes Nylon, thermoplastic elastomers, polyolefins, polystyrene, engineering plastics, biodegradable materials, and over 300 other types of high-performance and functionalized products.

ORINKO Polyamide 610 (PA610)

is a long-chain nylon, which is made by condensation polymerization of ethylenediamine and dodecanedioic acid as raw materials. The raw material dodecanedioic acid can be produced through chemical synthesis or microbial fermentation. ORINKO integrates PA610 forward and backward, with our own factories in backward raw material production, forward resin polymerization and polyamide compound.

Polyamide 610 Resin: Unrivaled Thermal Stability

Polyamide 610 (PA610) resin stands out for its exceptional thermal stability, making it an ideal choice among thermoplastics for applications that involve exposure to high temperatures. This resin is produced through the precise polymerization of hexamethylene diamine and sebacic acid, creating a molecular structure that offers outstanding resistance to thermal degradation.

Applications in High-Temperature Environments:

Automotive Under-the-Hood Components: PA610 is commonly used in the automotive industry for creating under-the-hood parts such as engine covers, air intake systems, and other components that must withstand the

high temperatures generated by the engine.

Industrial Machinery Parts: In industrial machinery, PA610 is utilized for manufacturing gears, bearings, and housings. Its thermal stability ensures reliable performance in applications where heat is produced during operation.

Our Nylon/Polyamide Types

Nylon 612 Raw resin

Nylon 612-Halogen-free Flame Retardant

Nylon 612-Powder Coating

Nylon 612-Reinforced for Fule Lines

Nylon 612-Carbon/Glass Fiber Reinforced

Nylon 1012 Raw resin

Nylon 1012 -Reinforced for Fuel line Outer Coating

Nylon 1012-Glass Fiber Reinforced

Nylon 1012-Elastomeric

Pure PA610 is commonly used for toothbrush bristles, monofilaments, and cable core rings. It is also utilized as an internal coating for petroleum pipelines and as a coating for cables.

The modified PA610 can be widely used in the automotive industry, machinery manufacturing(ol containers, textile machinery parts), and in the electronicindustry for making battrey casings, instrument rails, etc. It can also be used as bristles of toothbrushes, monoflaments and cablecorerings, etc.lt can be customized in injection and extrusion grade according to customers requirements.

Automotive

Battery

Cable

Toothbrushe

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

As a full service provider Orinko

will give you all the necessary technical support

and marketing advice to enable you to process

and sell your products successfully.

Get in touch with us to find the perfect solution for your application.

As a premier publicly listed enterprise in China, we specialize in polymer-enhanced materials like polyamides, polyolefins, polystyrene, and advanced engineering plastics. Our portfolio boasts collaborations with numerous automotive giants, spanning Volkswagen, Ford, Toyota, Honda, Audi, and several other renowned manufacturers.

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

Initiate global layout and shoulder global supply responsibilities bravely

Global R&D Center

•Shanghai

Synthesis base

•Weifang, Shandong Province

Domestic modification R&D and production base

① East: Hefei + Anqing, Anhui Province

② West: Tongliang, Chongqing

③ South: Foshan, Guangdong Province

Inject impetus into the enterprise and industrial development with continuous innovation investment

Innovation capability-provide overall solutions

Start from home appliances, serve many industry leaders and become their strategic partners

With decades of experience in the industry, Orink has established itself as a leader in the modified materials sector. We are one of the largest and most widely recognized enterprises in China, known for our extensive range of high-molecular modified materials. Our product portfolio includes Nylon, thermoplastic elastomers, polyolefins, polystyrene, engineering plastics, biodegradable materials, and over 300 other types of high-performance and functionalized products.

No.2 Luhua Road,Boyan Science Park,Hefei,Anhui Province,China