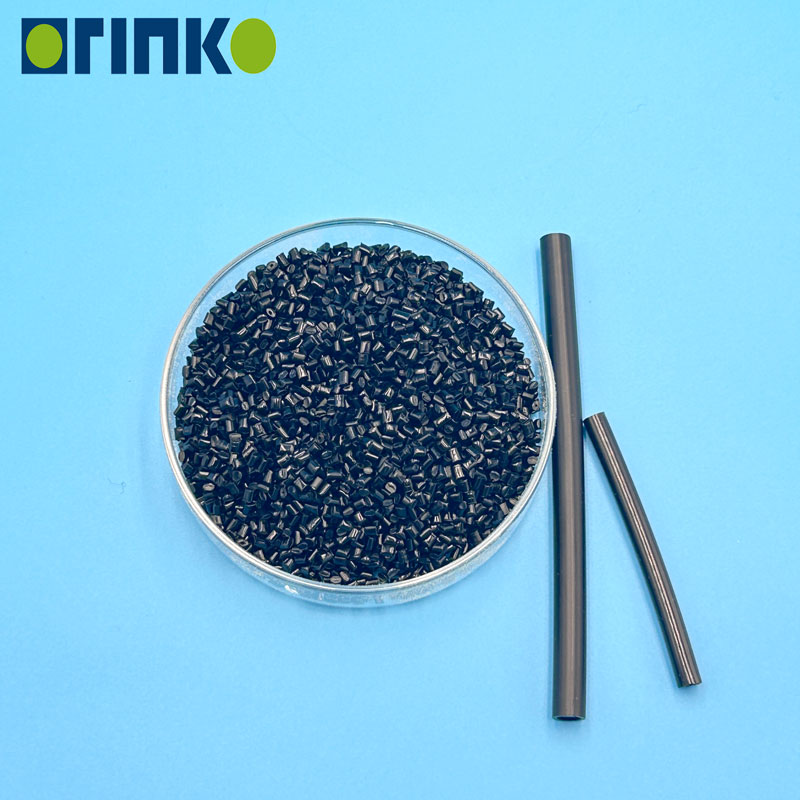

ORINKO Pa6/Pa66 Gf30 Granules

Feature Description:

High strength and high rigidity: After adding reinforcing materials such as glass fiber and carbon fiber, the strength and rigidity are greatly improved. For example, PA66 with 30% glass fiber added can have a tensile strength of more than 180MPa, which is about twice that of pure PA66. It is suitable for manufacturing mechanical parts that withstand large external forces.

Good heat resistance: The heat deformation temperature of pure PA66 is about 65℃, and it can reach more than 200℃ after modification. It can still maintain good dimensional stability and mechanical properties at high temperatures and can be used for parts in high-temperature working environments.

Excellent wear resistance and self-lubrication: After adding lubricants such as molybdenum disulfide and silicone oil, the friction coefficient is significantly reduced, the wear resistance is greatly improved, and the wear resistance is far superior to ordinary engineering plastics. It is suitable for parts such as gears and bearings that require long-term friction and movement.

Good chemical resistance: It has a certain chemical resistance. After modification, its tolerance to acids, alkalis, organic solvents, etc. is further enhanced. It can also maintain stable performance in chemical corrosion environments and extend its service life.

Customizable flame retardancy: After adding flame retardants, different flame retardancy levels can be achieved, such as UL94 V-0 level, which can effectively reduce the risk of fire in fields with high fire protection requirements such as electronic appliances.

Contact Information

Email:futao@orinko.com.cn

Whatsapp/Wechat:+86 13013179882

Application Area

Automotive industry: used to manufacture automotive engine parts, body structural parts, interior parts, etc. For example, the engine intake manifold can work stably under high temperature, high pressure and complex chemical environment by utilizing the high strength, heat resistance and chemical resistance of modified PA66.

Electronic appliances: widely used in the housing, sockets, plugs, wires and cables of electronic equipment. For example, the shell of mobile phone charger uses flame-retardant modified PA66, which can not only ensure good insulation performance, but also prevent fire in unexpected situations.

Mechanical manufacturing: can manufacture mechanical parts such as gears, bearings, cams, etc. With its high strength, wear resistance and self-lubrication, it can effectively reduce the wear of mechanical parts and improve the operating efficiency and service life of equipment.

Aerospace: In the field of aerospace, modified PA66 can be used to manufacture some non-critical structural parts and interior parts. Utilizing its lightweight and good comprehensive performance, it helps to reduce the weight of aircraft and improve fuel efficiency.