Tel/Whatsapp: +86-13013179882 Email: futao@orinkoplastic.com

PBT

ORINKO

Property:

Cold and heat shock resistance

Voltage resistance

High strength

Flame retardant Refrigerant resistance

Nylon 610 Raw resin

Nylon 610-Halogen-free, Phosphorus-free, Flame Retardant

Nylon 610-Enhanced anti-static

Nylon 610-Glass Fiber Reinforced and Toughened

Corrosion-resistant reinforced PA610 for pipelines

Nylon 612 Raw resin

Nylon 612-Halogen-free Flame Retardant

Nylon 612-Powder Coating

Nylon 612-Reinforced for Fule Lines

Nylon 612-Carbon/Glass Fiber Reinforced

Nylon 1012 Raw resin

Nylon 1012 -Reinforced for Fuel line Outer Coating

Nylon 1012-Glass Fiber Reinforced

Nylon 1012-Elastomeric

Halogen-free Flame Retardant

Halogen Flame Retardant

Glass Fiber Reinforced

Automotive industry: Modified PBT is mainly used for automotive wiper brackets, automotive headlight bezels, automotive transmission gear boxes, windshield top bollards, motor shells and other components.

Electronic appliances: PBT is widely used in the field of electronic appliances, such as electronic connectors, cooling fans, bases and shells of energy-saving lamps, etc. PBT is widely used due to its mechanical properties, solvent resistance, good formability, and low price.

Electrical industry: PBT can be used for components such as transformers, relay spools and housings, which require materials with good insulation, good heat resistance, high flame retardancy, high fluidity, high strength and toughness.

Other uses: PBT can also be used to prepare skate soles, sockets, switches, tuner housings, vacuum cleaner elements, electric fans, hair dryer housings, fiber optic connectors, etc.

Insulation Fram

Rotor

Fan Blade

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

Smart Factory

•National Pilot Demonstration Project for the Integration of Manufacturing and Internet Development: manufacturing and lean quality control capabilities for modified plastics.

•Anhui Industrial Internet Enterprise Level Platform: full lifecycle control industrial Internet platform for the production of new multi-functional composite materials.

•Hefei Top Ten Industrial Empowerment Scenarios Demonstration Project: Demonstration of digital collaborative industrial internet in the high-performance fireproof material industry chain.

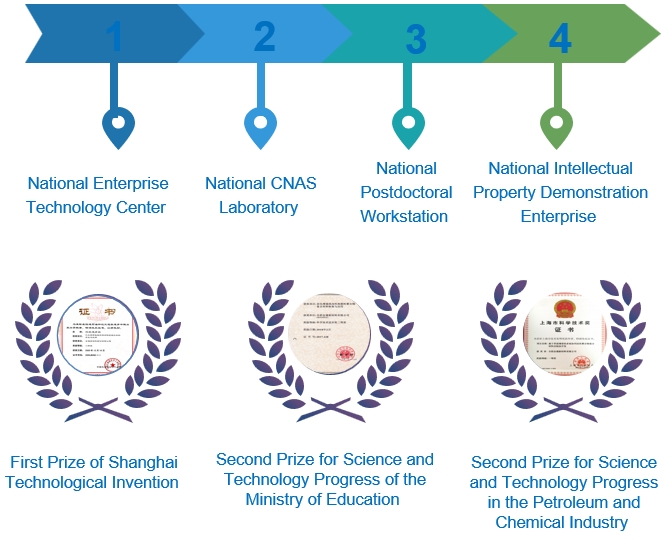

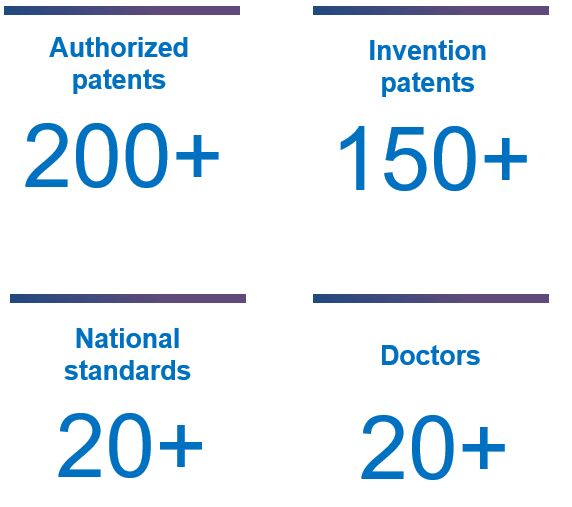

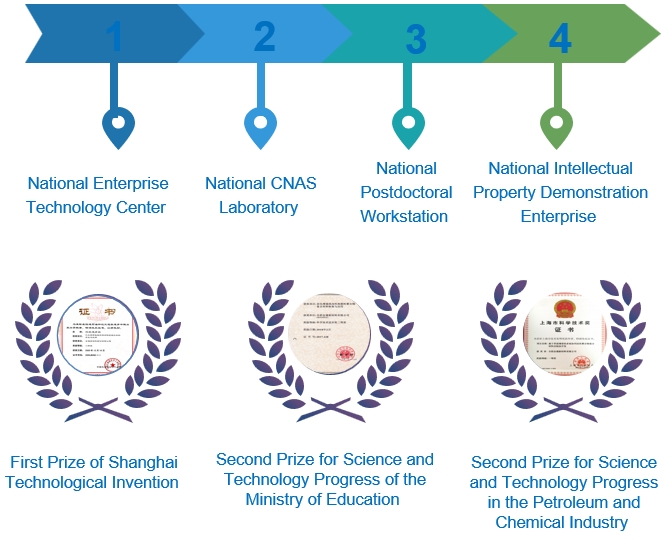

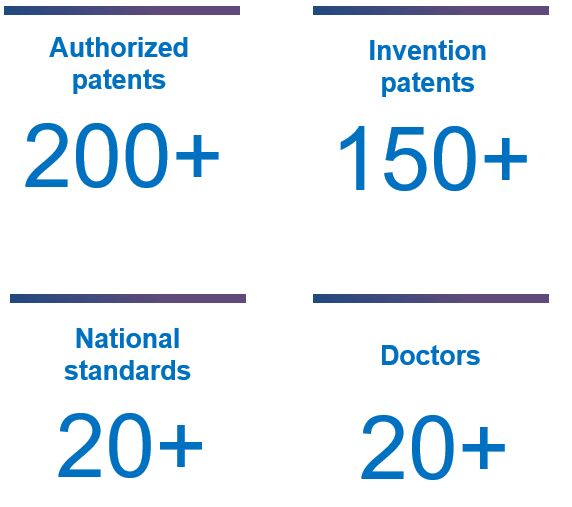

Inject impetus into the enterprise and industrial development with continuous innovation investment

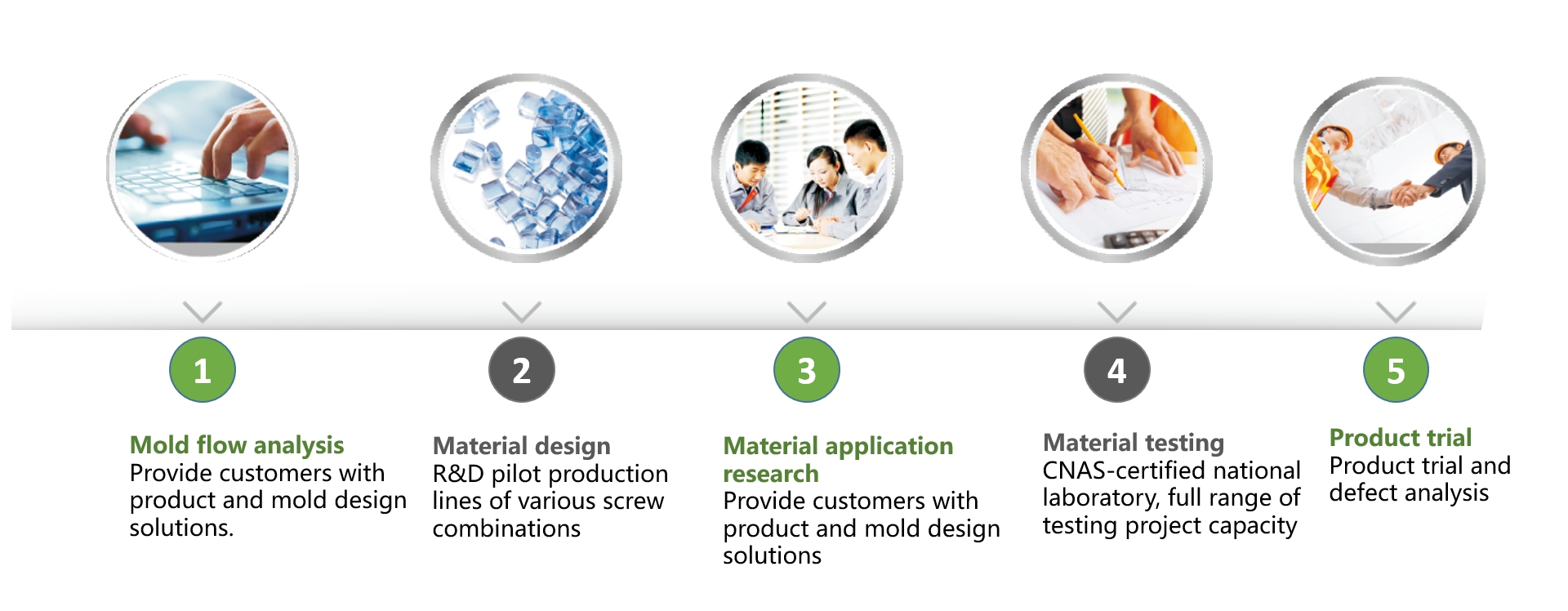

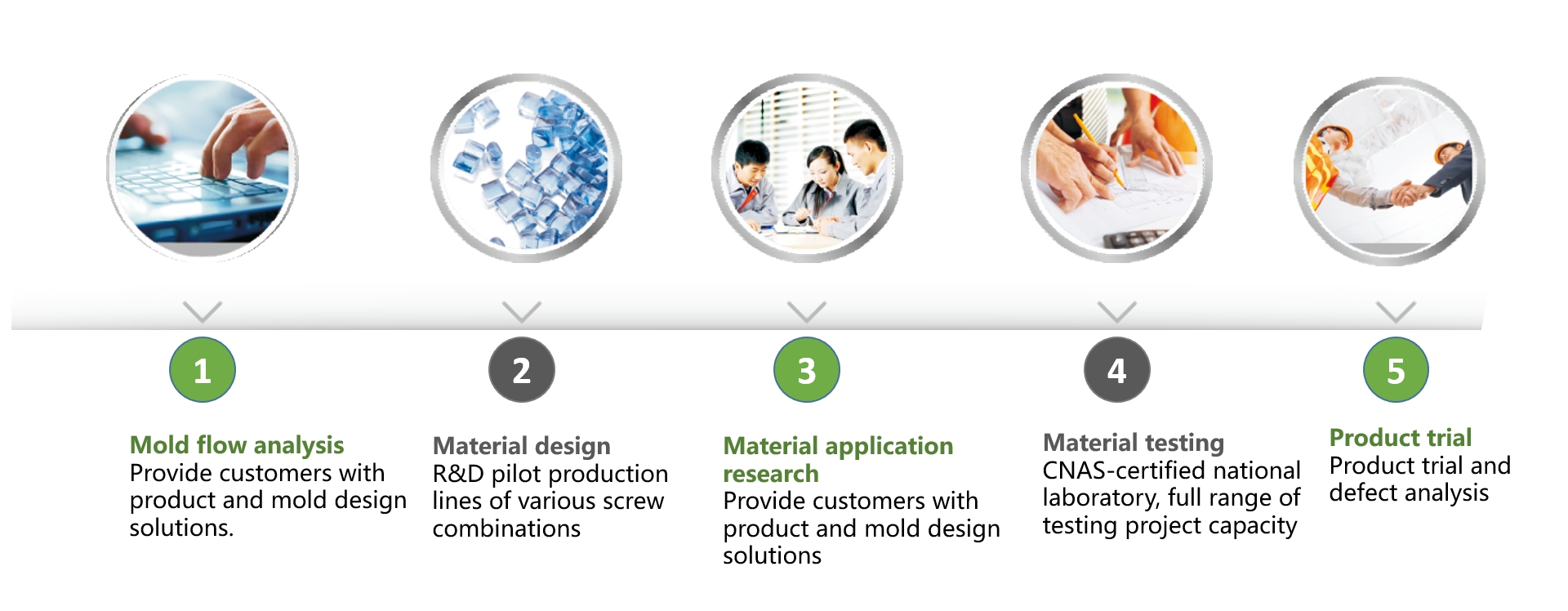

Innovation capability-provide overall solutions

Start from home appliances, serve many industry leaders and become their strategic partners

Orink Advanced Materials Co., Ltd contains Nylon, Thermplastic Elastomer,Polyolefines, Polystryrene, Engineering plastics,biodegradable mateirals and many other product platforms, including over 300 various kinds of high-molecular high-performance and functionalized products.

Property:

Cold and heat shock resistance

Voltage resistance

High strength

Flame retardant Refrigerant resistance

Nylon 610 Raw resin

Nylon 610-Halogen-free, Phosphorus-free, Flame Retardant

Nylon 610-Enhanced anti-static

Nylon 610-Glass Fiber Reinforced and Toughened

Corrosion-resistant reinforced PA610 for pipelines

Nylon 612 Raw resin

Nylon 612-Halogen-free Flame Retardant

Nylon 612-Powder Coating

Nylon 612-Reinforced for Fule Lines

Nylon 612-Carbon/Glass Fiber Reinforced

Nylon 1012 Raw resin

Nylon 1012 -Reinforced for Fuel line Outer Coating

Nylon 1012-Glass Fiber Reinforced

Nylon 1012-Elastomeric

Halogen-free Flame Retardant

Halogen Flame Retardant

Glass Fiber Reinforced

Automotive industry: Modified PBT is mainly used for automotive wiper brackets, automotive headlight bezels, automotive transmission gear boxes, windshield top bollards, motor shells and other components.

Electronic appliances: PBT is widely used in the field of electronic appliances, such as electronic connectors, cooling fans, bases and shells of energy-saving lamps, etc. PBT is widely used due to its mechanical properties, solvent resistance, good formability, and low price.

Electrical industry: PBT can be used for components such as transformers, relay spools and housings, which require materials with good insulation, good heat resistance, high flame retardancy, high fluidity, high strength and toughness.

Other uses: PBT can also be used to prepare skate soles, sockets, switches, tuner housings, vacuum cleaner elements, electric fans, hair dryer housings, fiber optic connectors, etc.

Insulation Fram

Rotor

Fan Blade

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

Smart Factory

•National Pilot Demonstration Project for the Integration of Manufacturing and Internet Development: manufacturing and lean quality control capabilities for modified plastics.

•Anhui Industrial Internet Enterprise Level Platform: full lifecycle control industrial Internet platform for the production of new multi-functional composite materials.

•Hefei Top Ten Industrial Empowerment Scenarios Demonstration Project: Demonstration of digital collaborative industrial internet in the high-performance fireproof material industry chain.

Inject impetus into the enterprise and industrial development with continuous innovation investment

Innovation capability-provide overall solutions

Start from home appliances, serve many industry leaders and become their strategic partners

Orink Advanced Materials Co., Ltd contains Nylon, Thermplastic Elastomer,Polyolefines, Polystryrene, Engineering plastics,biodegradable mateirals and many other product platforms, including over 300 various kinds of high-molecular high-performance and functionalized products.

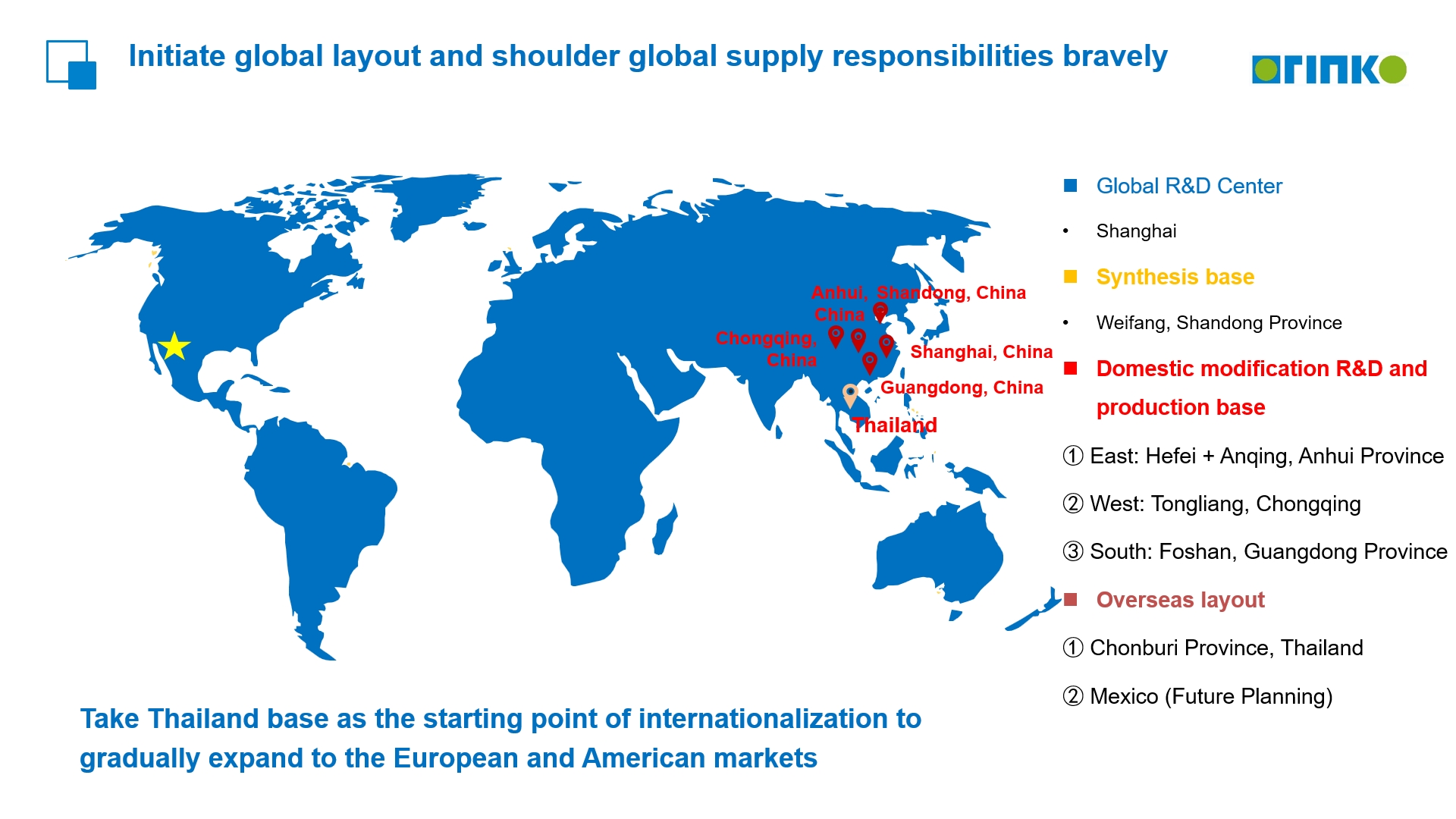

No.2 Luhua Road,Boyan Science Park,Hefei,Anhui Province,China