Tel/Whatsapp: +86-13013179882 Email: futao@orinkoplastic.com

| Availability: | |

|---|---|

| Quantity: | |

ORINKO

Modified PA610 is a material that undergoes specific performance improvements on polyamide-610 (PA610). PA610 itself is a translucent, milky white polymer with characteristics such as low specific gravity, low crystallinity, good dimensional stability, and self-extinguishing properties. Its strength lies between nylon-6 and nylon-66, with a relatively low water absorption rate and good heat resistance. Modified PA610 further optimizes these properties, typically featuring:

Odorless, Tasteless, and Non-toxic: Modified PA610 retains the odorless, tasteless, and non-toxic characteristics of PA610, while adding mold resistance, making it more suitable for food contact materials and medical devices where safety requirements are high.

High Strength and Toughness: Through modification, the strength and impact toughness of PA610 are significantly improved, meeting the mechanical performance demands of higher requirements.

Enhanced Heat Resistance: Modified PA610 exhibits improved heat resistance, maintaining stable performance at higher temperatures and broadening its application range.

Low Friction Coefficient: Modified PA610 has a small friction coefficient, and products made from it have good sound damping properties, producing low noise during operation, suitable for applications requiring noise reduction.

Chemical Resistance: Modified PA610 is resistant to weak acids, weak bases, and general solvents, improving its stability in chemical environments.

In addition, modified PA610 may also have enhanced properties such as flame retardancy and low-temperature resistance to meet the application needs of different fields. This material has broad application prospects in the automotive, electrical, and precision plastic parts industries.

it can be widely used in the automotive industry, machinery manufacturingloil containers, textile machinery parts, and in the electronicindustry for making battrey casings, instrument rails, etc. it can alo be used as bristles of toothbrushes, monofilaments and cablecorerings, etc. lt can be customized in injection and extrusion grade according to customers requirements.

| Automotive - Engine Covers/Housings Cable Insulation and Jacketing Electrical & Electronic Plastics Electrical Encapsulation Materials Electrical Insulation Polymers Electrical Motor Insulation Electronic & Electrical Connectors High-Performance Materials for 3D Printing Innovative Furniture Design | Mobile Device Casings & Internal Components Engine Oil Pan & Cylinder Head Seals Solar Panels & Their Components Sports Equipment Plastics Appliance-Grade Polymers Oil & Gas Industry Polymers Long-Distance Railway Technology Solutions Thermoplastic Conduits & Elastomer Hoses Transformer Isolation Materials |

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

We will be happy to assist you in selecting the material

that will best meet your requirements or provide you with a

tailor-made formulation.

Tel/Whatsapp:+86-13013179882 Email:futao@orinkoplastic.com

Get in touch with us to find the perfect solution for your application.

We rank among the preeminent publicly traded enterprises in China specializing in polymer-modified materials, which encompass a broad range including polyamides, polyolefins, polystyrenes, and engineering-grade plastics. Our portfolio boasts collaborations with numerous prestigious automotive manufacturers, including Volkswagen, Ford, Toyota, Honda, Audi, and numerous others.

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

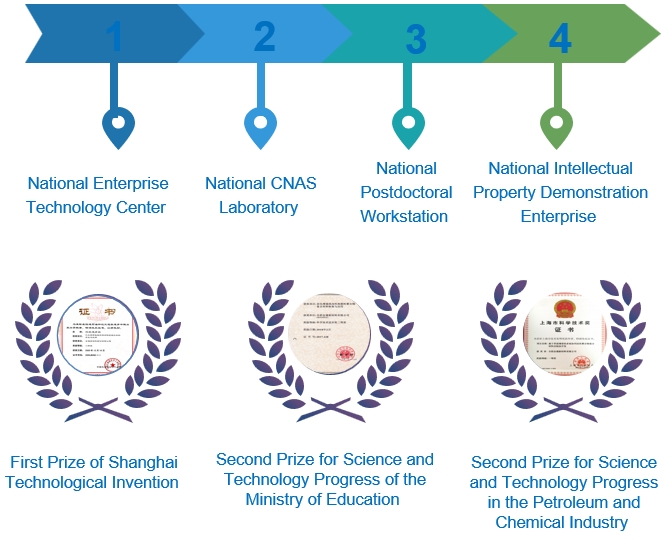

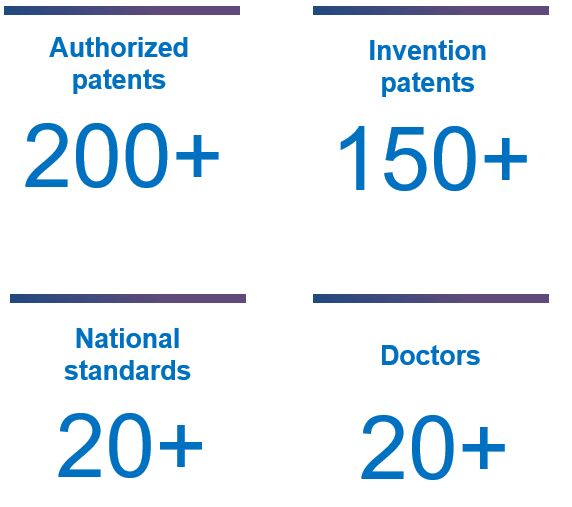

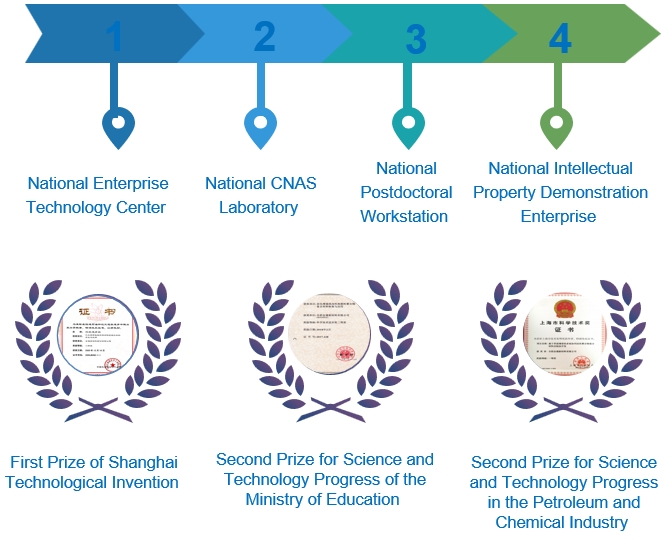

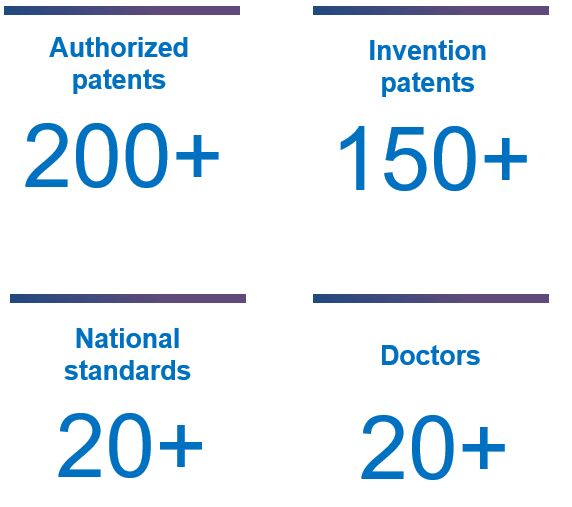

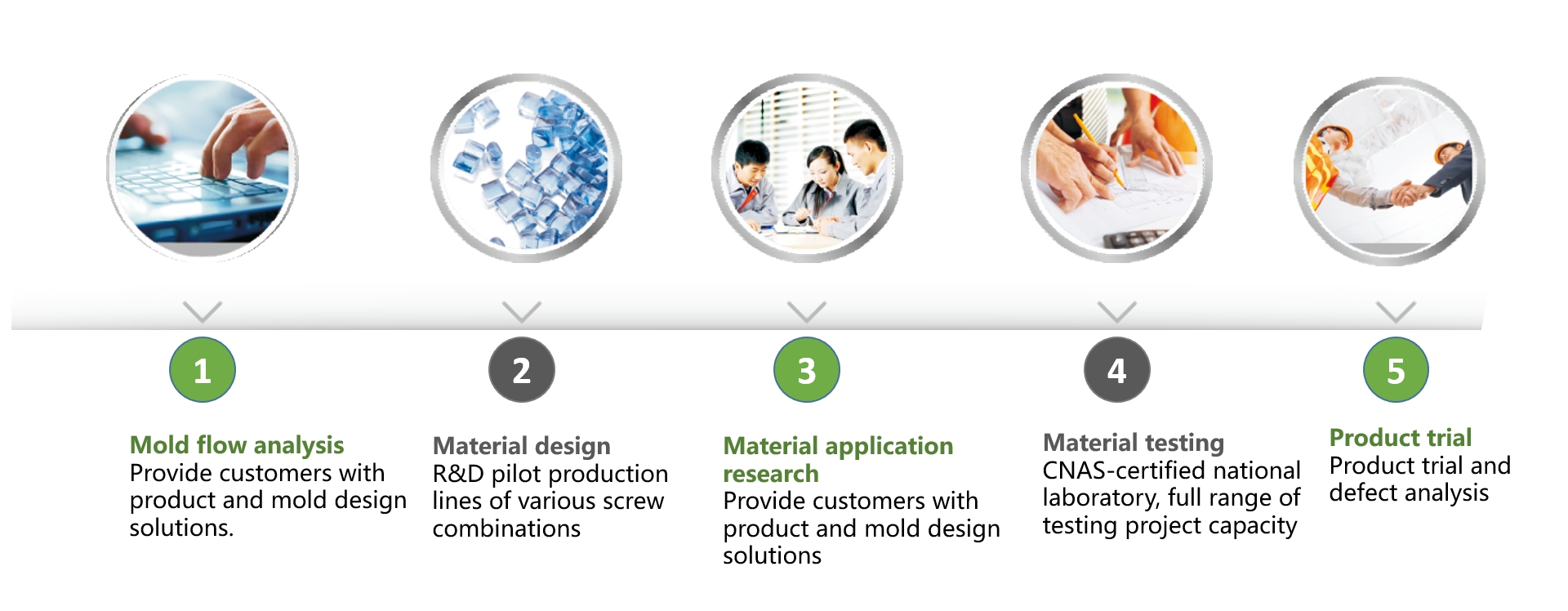

Inject impetus into the enterprise and industrial development with continuous innovation investment

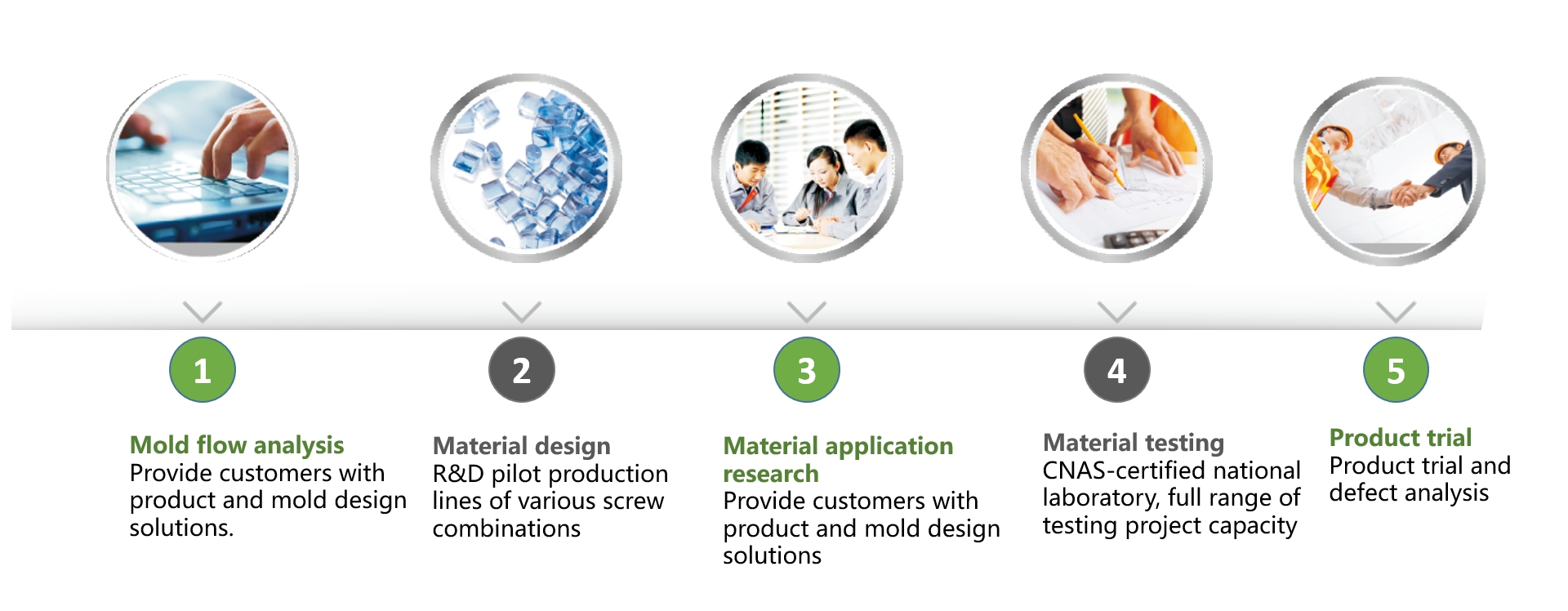

Innovation capability-provide overall solutions

Start from home appliances, serve many industry leaders and become their strategic partners

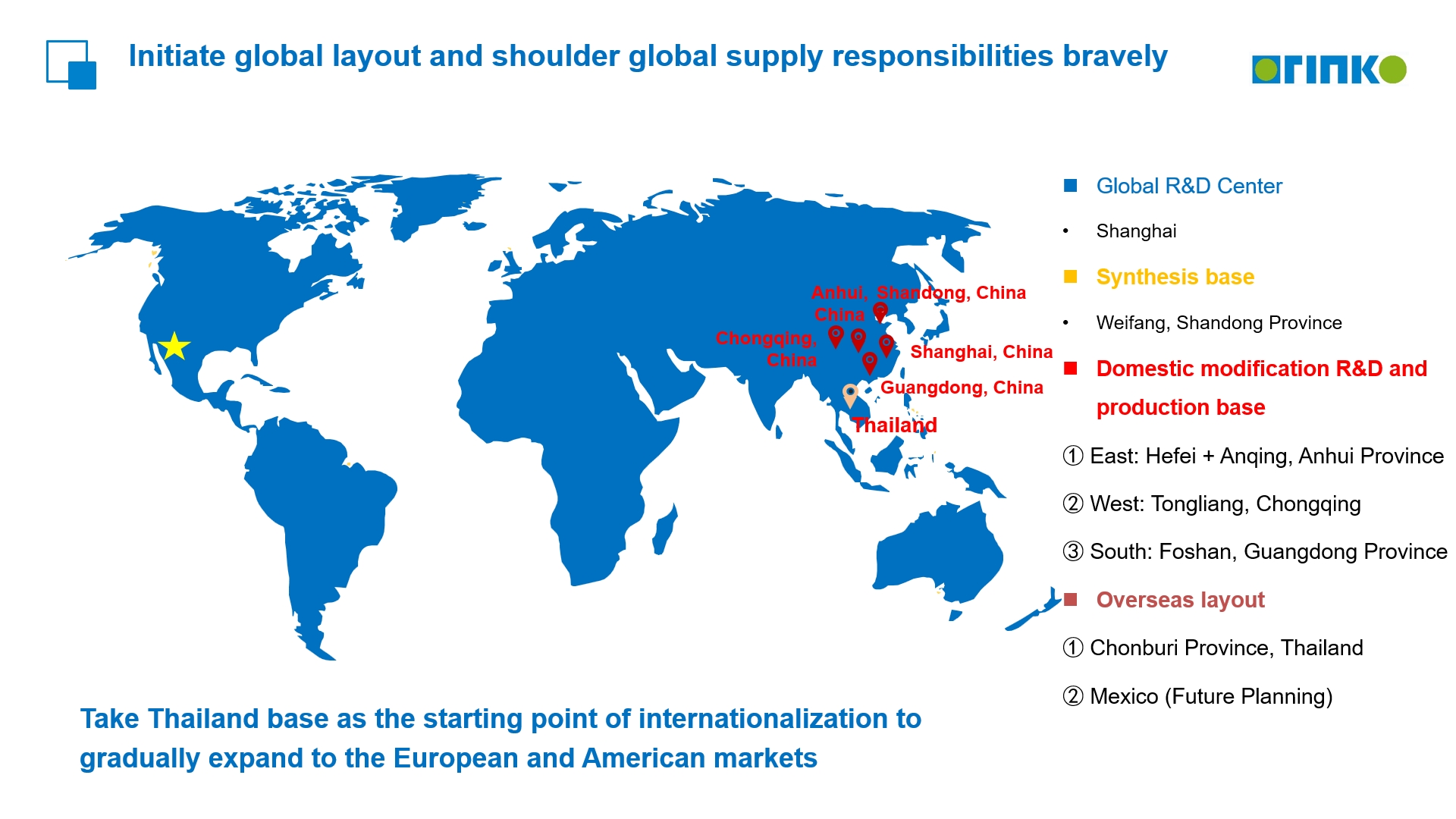

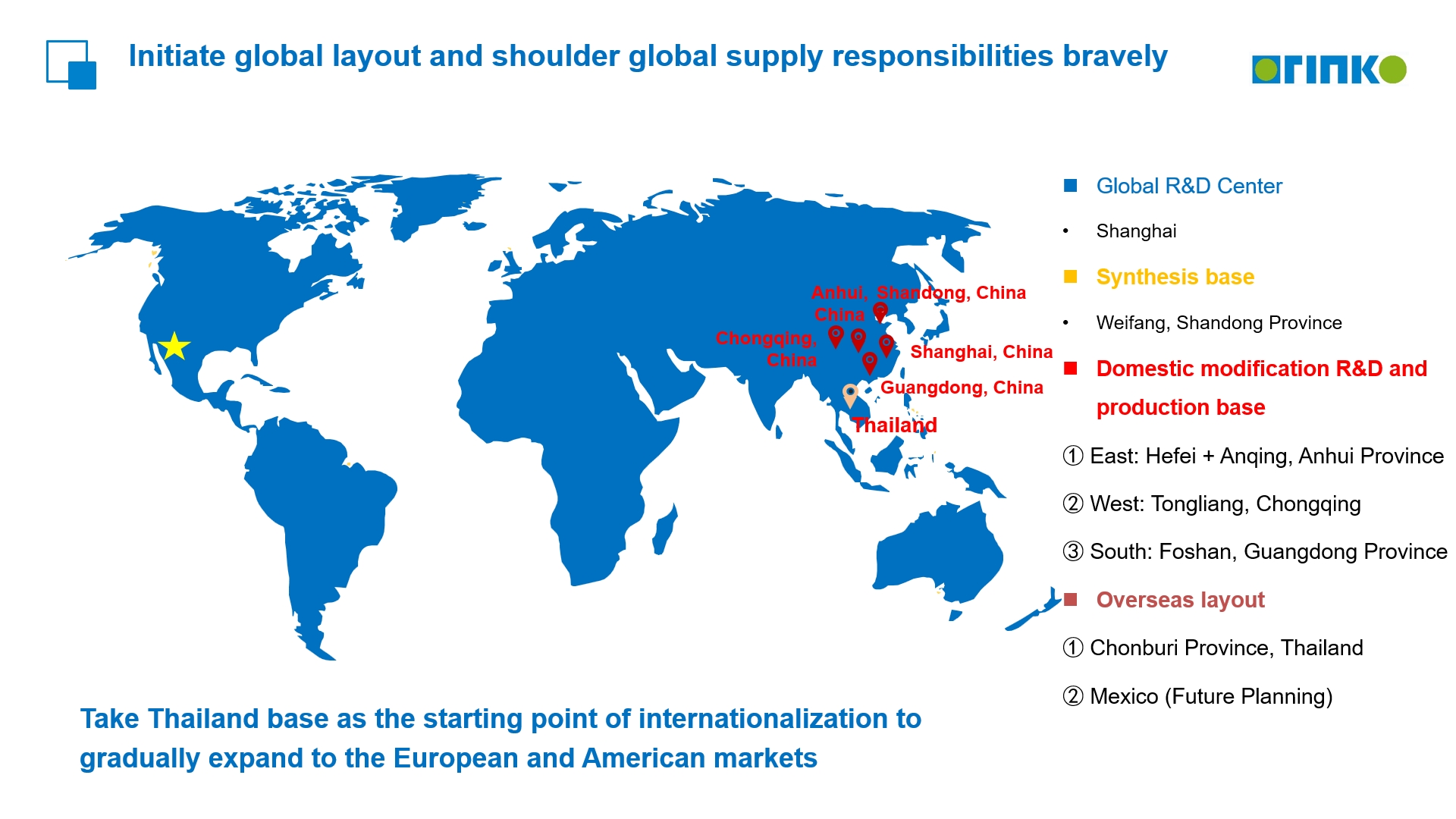

Orinko Advanced Materials Co., Ltd. specializes in the research, development, manufacturing, and distribution of advanced high-molecular modified materials, with a mission to furnish customers with comprehensive, high-performance, and multifunctional material solutions.

With decades of dedicated service to the industry, Orinko has emerged as a leading player in the modified materials sector, boasting a comprehensive competitive edge that sets it apart. As a result, the company stands as one of the largest and most widely recognized enterprises in China for high-molecular modified materials, enjoying a vast customer base.

Orinko's product portfolio encompasses diverse platforms such as Nylon, Thermoplastic Elastomers, Polyolefins, Polystyrene, Engineering Plastics, and Biodegradable Materials, offering a comprehensive range of over 300 distinct high-molecular, high-performance, and functionalized products tailored to meet various application needs.

Modified PA610 is a material that undergoes specific performance improvements on polyamide-610 (PA610). PA610 itself is a translucent, milky white polymer with characteristics such as low specific gravity, low crystallinity, good dimensional stability, and self-extinguishing properties. Its strength lies between nylon-6 and nylon-66, with a relatively low water absorption rate and good heat resistance. Modified PA610 further optimizes these properties, typically featuring:

Odorless, Tasteless, and Non-toxic: Modified PA610 retains the odorless, tasteless, and non-toxic characteristics of PA610, while adding mold resistance, making it more suitable for food contact materials and medical devices where safety requirements are high.

High Strength and Toughness: Through modification, the strength and impact toughness of PA610 are significantly improved, meeting the mechanical performance demands of higher requirements.

Enhanced Heat Resistance: Modified PA610 exhibits improved heat resistance, maintaining stable performance at higher temperatures and broadening its application range.

Low Friction Coefficient: Modified PA610 has a small friction coefficient, and products made from it have good sound damping properties, producing low noise during operation, suitable for applications requiring noise reduction.

Chemical Resistance: Modified PA610 is resistant to weak acids, weak bases, and general solvents, improving its stability in chemical environments.

In addition, modified PA610 may also have enhanced properties such as flame retardancy and low-temperature resistance to meet the application needs of different fields. This material has broad application prospects in the automotive, electrical, and precision plastic parts industries.

it can be widely used in the automotive industry, machinery manufacturingloil containers, textile machinery parts, and in the electronicindustry for making battrey casings, instrument rails, etc. it can alo be used as bristles of toothbrushes, monofilaments and cablecorerings, etc. lt can be customized in injection and extrusion grade according to customers requirements.

| Automotive - Engine Covers/Housings Cable Insulation and Jacketing Electrical & Electronic Plastics Electrical Encapsulation Materials Electrical Insulation Polymers Electrical Motor Insulation Electronic & Electrical Connectors High-Performance Materials for 3D Printing Innovative Furniture Design | Mobile Device Casings & Internal Components Engine Oil Pan & Cylinder Head Seals Solar Panels & Their Components Sports Equipment Plastics Appliance-Grade Polymers Oil & Gas Industry Polymers Long-Distance Railway Technology Solutions Thermoplastic Conduits & Elastomer Hoses Transformer Isolation Materials |

Packing Details : Standard Packing(lnner /Aluminum Film ,Outer/Paper bag or woven bag).

Packaging Details:25kg/bag,or 750 kg/1000kg per jumbo bag

Delivery Details :T+10days

Port of departure:Wuhu, Shanghai,Ningbo,Guangzhou.

We will be happy to assist you in selecting the material

that will best meet your requirements or provide you with a

tailor-made formulation.

Tel/Whatsapp:+86-13013179882 Email:futao@orinkoplastic.com

Get in touch with us to find the perfect solution for your application.

We rank among the preeminent publicly traded enterprises in China specializing in polymer-modified materials, which encompass a broad range including polyamides, polyolefins, polystyrenes, and engineering-grade plastics. Our portfolio boasts collaborations with numerous prestigious automotive manufacturers, including Volkswagen, Ford, Toyota, Honda, Audi, and numerous others.

Certificate

ISO9001

ISO14001

ISO45001

IATF16949

Inject impetus into the enterprise and industrial development with continuous innovation investment

Innovation capability-provide overall solutions

Start from home appliances, serve many industry leaders and become their strategic partners

Orinko Advanced Materials Co., Ltd. specializes in the research, development, manufacturing, and distribution of advanced high-molecular modified materials, with a mission to furnish customers with comprehensive, high-performance, and multifunctional material solutions.

With decades of dedicated service to the industry, Orinko has emerged as a leading player in the modified materials sector, boasting a comprehensive competitive edge that sets it apart. As a result, the company stands as one of the largest and most widely recognized enterprises in China for high-molecular modified materials, enjoying a vast customer base.

Orinko's product portfolio encompasses diverse platforms such as Nylon, Thermoplastic Elastomers, Polyolefins, Polystyrene, Engineering Plastics, and Biodegradable Materials, offering a comprehensive range of over 300 distinct high-molecular, high-performance, and functionalized products tailored to meet various application needs.

No.2 Luhua Road,Boyan Science Park,Hefei,Anhui Province,China