Tel/Whatsapp: +86-13013179882 Email: futao@orinkoplastic.com

| Availability: | |

|---|---|

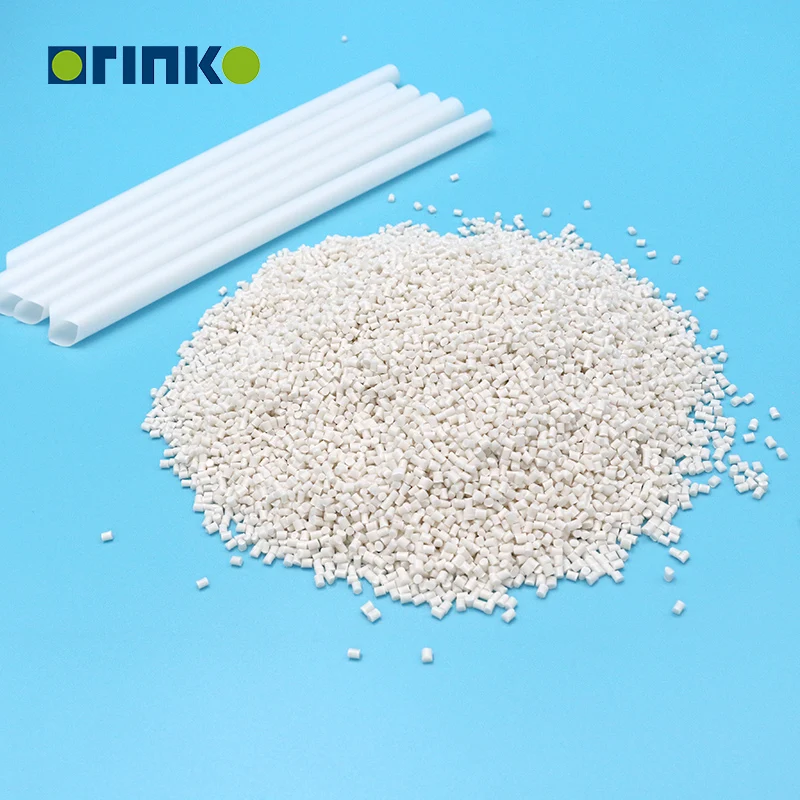

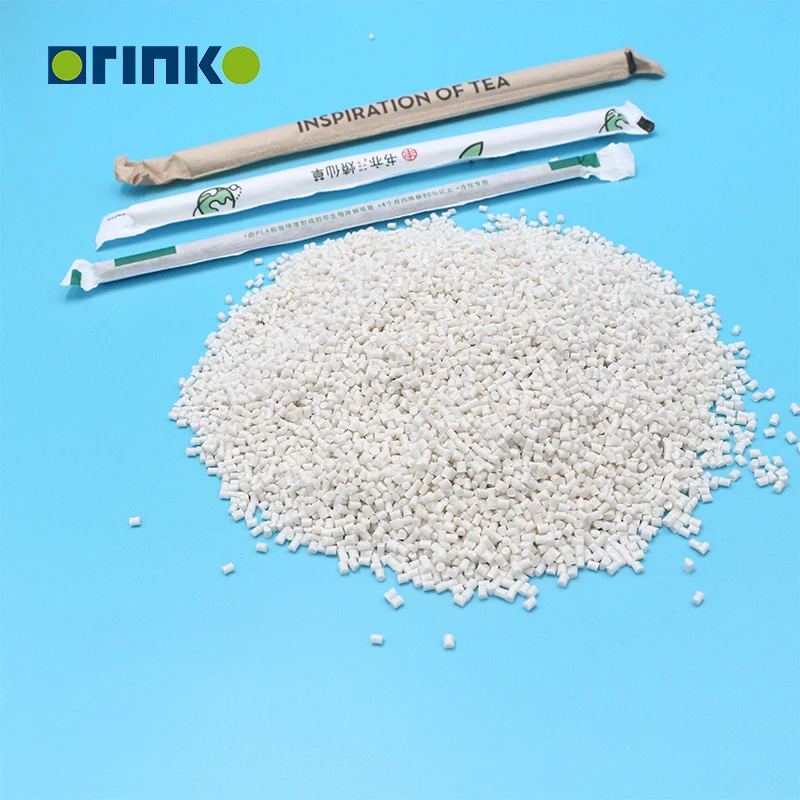

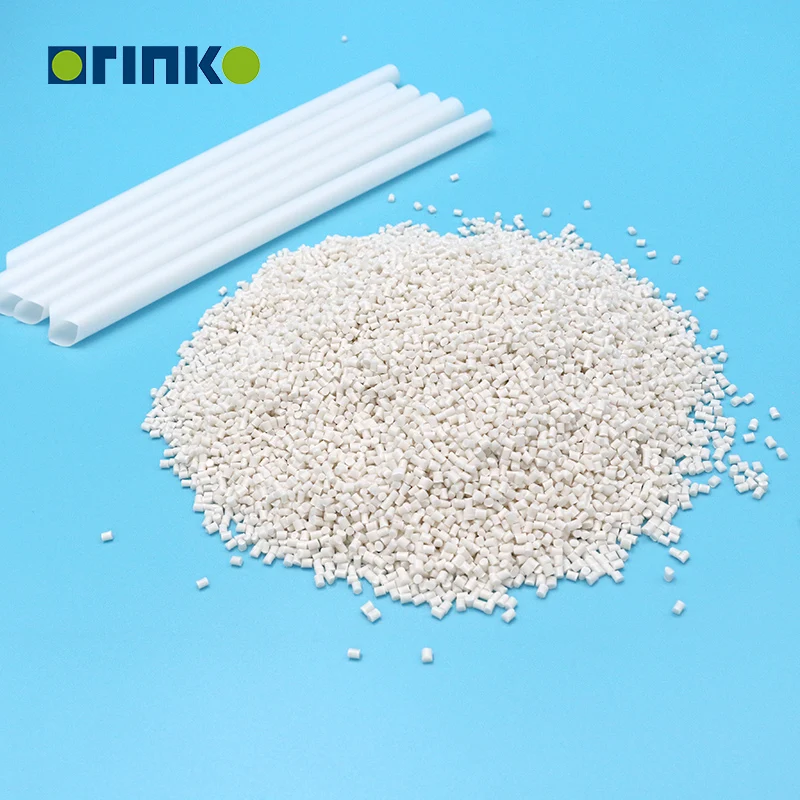

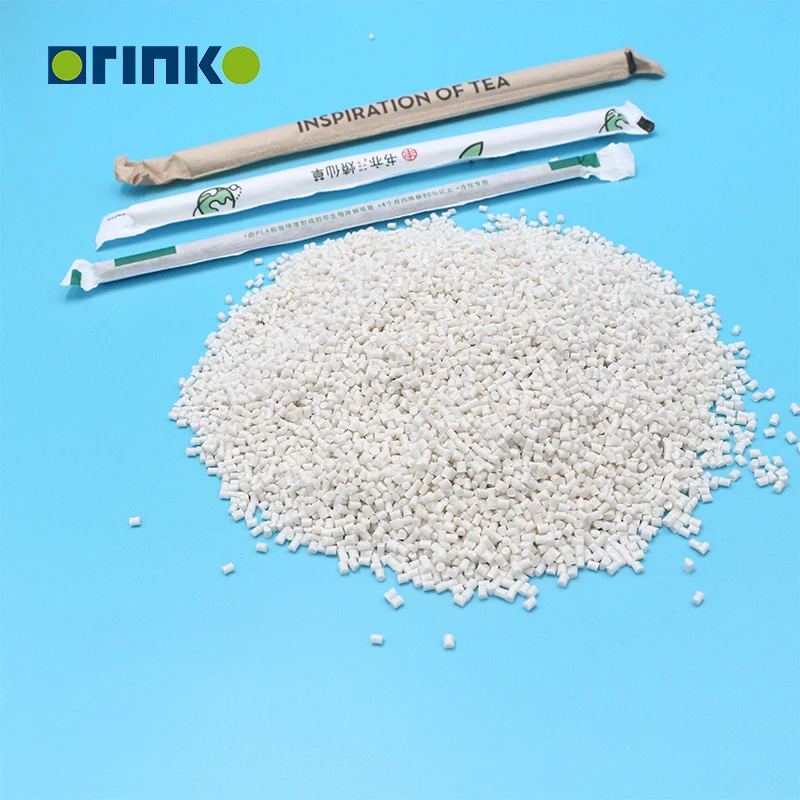

H8000-1 Series

Orinko

Polylactic acid (PLA) is a new type of biodegradable material made from starch raw materials from renewable plant resources such as corn.

Polylactic acid is synthesized from starch raw materials by chemical methods. It has good biodegradability and can be completely degraded by microorganisms in nature after use, eventually generating carbon dioxide and water, without polluting the environment, which is very beneficial to protect the environment and is recognized as an environmentally friendly material.

Good mechanical and physical properties.

Polylactic acid is suitable for film blowing, injection molding, blister molding, and thermoforming processing methods. It is easy to process and widely used. It can be used in plastic products, shopping bags,disposable tableware and cutlery, non-woven fabrics, industrial and civilian fabrics. And agricultural fabrics, health care fabrics, rags, sanitary products, outdoor UV protection fabrics, tent fabrics, floor mats, etc.

As a full service provider, Orinko will give you all the necessary technical support and marketing advice to enable you to process and sell your products successfully.

We will be happy to assist you in selecting the material that will best meet your requirements or provide you with a

tailor-made formulation.

Our modified bio plastic including 4 series to meet application needs under multiple scenes.

OrinBio M1000, M2000, M5000 and H8000.

Extrusion molding

With high fluidity, low odor, high toughness,and can be industrially composted for the production of disposable low/heigh resistant straws

Biodegradable materials for disposable high/low heat resistant straws,such as straight straw, art straw, colorful straw

| Item | Unit | Test Method | H8000-1A/B/C | H8000-1D | H8000-1E | H8000-1G | H8000-1H |

| Moldinging Method | Extrusion molding | Extrusion molding | Extrusion molding | Extrusion molding | Extrusion molding | ||

| Density | g/cm3 | GB/T1033 | 1.32±0.05 | 1.34±0.05 | 1.35±0.05 | 1.36±0.05 | 1.37±0.05 |

| Melt Flow Rate | g/10min | GB/T3682 | 4-6 | 4-7 | 4-7 | 4-7 | 4-6 |

| Application | High Heat resistant straight straws | High Heat resistant art straws | Low Heat resistant art straws | Standard straws | High Heat resistant straws |

Name1

Name2

Name3

Name4

Our modified OrinBio products including 4 series to meet application needs under multiple scenes.

OrinBio M1000, M2000, M5000 and H8000

| Typical display | PLA Resin | Modified Biodegradable Material | ||||||||

| HT102 | HT202 | HT503 | M1000 | M2000 | M5000 | H8000-1 | H8000-2 | H8000-5 | ||

| Density | g/cm3 | 1.24±0.05 | 1.24±0.05 | 1.24±0.05 | 1.20-1.30 | 1.20-1.30 | 1.25-1.45 | 1.30-1.34 | 1.32-1.35 | 1.25-1.35 |

| Melt Flow Rate | (g/10min) | 2-9 | 10-25 | 2-6 | 2-4 | 2-4 | 2-4 | 4-6 | 4-7 | 3-10 |

· The values listed are typical and should not be interpreted as specifications.

· For availability and more model parameters, please contact account manager.

OrinBio M1000 series

Biodegradable materials for home compostable films

Made by blending and modifying biomaterial.

Features:Weather resistance and heat sealing strength of film and bags.

OrinBio M2000 series

Made by biodegradable materials and biomaterials blended and modified.

Features:Tensile strength and stiffness of film and bags.

OrinBio M5000 series

Biodegradable materials for industrial compostable film applications

Made by biodegradable material,biomaterials and inorganic minerals blended and modified.

Features:High tensile strength,high stiffness and high load bearing of film and bags.

OrinBio H8000 series

Biodegradable materials for thermoforming applications

Made by biodegradable materials and biomaterials blended and modified.

Features:High flexural modulus,high heat resistance,high toughness,and wide MFR.

Orinko Advanced Plastics Co.,Ltd is an innovator and is dedicated to developing high performance Polymer Materials.Including Biodegradable Plastics, Polyolefins, Polystyrenes, Polyethylene, Engineering Plastics etc.Our company has more than 1,800 employees and has four production and R&D bases (Hefei, Guangdong, Chongqing and Anqing) with a total production capacity of 500,000 tons of polymers.

Since 2008, with a R&D team of more than 350 people, We have more than 100 patents,and created more than 300 kinds of polymer modified materials its products to our customers that perform in their own markets and meet product performance criteria at reasonable cost.

We serve a global customer base with design and technical support. And our team members have a wealth of polymer experience and pride themselves on both a fundamental understanding of how our materials perform both technically and in our customers' markets.

100+ patents, 94 authorized patents, including 55 invention patents, and 10000+ cooperative customers.

8 major performance testing equipment

1.Thermal performance testing

2.emission detection

3.Photoelectric performance testing

4.Mechanical property testing

5.Flow performance testing

6.Flame retardant performance testing

7.Material Reliability Assessment

8.Material composition analysis

ISO9001-2015 Quality Management System

IATF16949 Automotive Industry Quality Management System

IECQ45001 Hazardous Substances Process Management System

ISO45001 Occupational Health Management System

ISO14001 Environmental Management System Intellectual Property Management System

Polylactic acid (PLA) is a new type of biodegradable material made from starch raw materials from renewable plant resources such as corn.

Polylactic acid is synthesized from starch raw materials by chemical methods. It has good biodegradability and can be completely degraded by microorganisms in nature after use, eventually generating carbon dioxide and water, without polluting the environment, which is very beneficial to protect the environment and is recognized as an environmentally friendly material.

Good mechanical and physical properties.

Polylactic acid is suitable for film blowing, injection molding, blister molding, and thermoforming processing methods. It is easy to process and widely used. It can be used in plastic products, shopping bags,disposable tableware and cutlery, non-woven fabrics, industrial and civilian fabrics. And agricultural fabrics, health care fabrics, rags, sanitary products, outdoor UV protection fabrics, tent fabrics, floor mats, etc.

As a full service provider, Orinko will give you all the necessary technical support and marketing advice to enable you to process and sell your products successfully.

We will be happy to assist you in selecting the material that will best meet your requirements or provide you with a

tailor-made formulation.

Our modified bio plastic including 4 series to meet application needs under multiple scenes.

OrinBio M1000, M2000, M5000 and H8000.

Extrusion molding

With high fluidity, low odor, high toughness,and can be industrially composted for the production of disposable low/heigh resistant straws

Biodegradable materials for disposable high/low heat resistant straws,such as straight straw, art straw, colorful straw

| Item | Unit | Test Method | H8000-1A/B/C | H8000-1D | H8000-1E | H8000-1G | H8000-1H |

| Moldinging Method | Extrusion molding | Extrusion molding | Extrusion molding | Extrusion molding | Extrusion molding | ||

| Density | g/cm3 | GB/T1033 | 1.32±0.05 | 1.34±0.05 | 1.35±0.05 | 1.36±0.05 | 1.37±0.05 |

| Melt Flow Rate | g/10min | GB/T3682 | 4-6 | 4-7 | 4-7 | 4-7 | 4-6 |

| Application | High Heat resistant straight straws | High Heat resistant art straws | Low Heat resistant art straws | Standard straws | High Heat resistant straws |

Name1

Name2

Name3

Name4

Our modified OrinBio products including 4 series to meet application needs under multiple scenes.

OrinBio M1000, M2000, M5000 and H8000

| Typical display | PLA Resin | Modified Biodegradable Material | ||||||||

| HT102 | HT202 | HT503 | M1000 | M2000 | M5000 | H8000-1 | H8000-2 | H8000-5 | ||

| Density | g/cm3 | 1.24±0.05 | 1.24±0.05 | 1.24±0.05 | 1.20-1.30 | 1.20-1.30 | 1.25-1.45 | 1.30-1.34 | 1.32-1.35 | 1.25-1.35 |

| Melt Flow Rate | (g/10min) | 2-9 | 10-25 | 2-6 | 2-4 | 2-4 | 2-4 | 4-6 | 4-7 | 3-10 |

· The values listed are typical and should not be interpreted as specifications.

· For availability and more model parameters, please contact account manager.

OrinBio M1000 series

Biodegradable materials for home compostable films

Made by blending and modifying biomaterial.

Features:Weather resistance and heat sealing strength of film and bags.

OrinBio M2000 series

Made by biodegradable materials and biomaterials blended and modified.

Features:Tensile strength and stiffness of film and bags.

OrinBio M5000 series

Biodegradable materials for industrial compostable film applications

Made by biodegradable material,biomaterials and inorganic minerals blended and modified.

Features:High tensile strength,high stiffness and high load bearing of film and bags.

OrinBio H8000 series

Biodegradable materials for thermoforming applications

Made by biodegradable materials and biomaterials blended and modified.

Features:High flexural modulus,high heat resistance,high toughness,and wide MFR.

Orinko Advanced Plastics Co.,Ltd is an innovator and is dedicated to developing high performance Polymer Materials.Including Biodegradable Plastics, Polyolefins, Polystyrenes, Polyethylene, Engineering Plastics etc.Our company has more than 1,800 employees and has four production and R&D bases (Hefei, Guangdong, Chongqing and Anqing) with a total production capacity of 500,000 tons of polymers.

Since 2008, with a R&D team of more than 350 people, We have more than 100 patents,and created more than 300 kinds of polymer modified materials its products to our customers that perform in their own markets and meet product performance criteria at reasonable cost.

We serve a global customer base with design and technical support. And our team members have a wealth of polymer experience and pride themselves on both a fundamental understanding of how our materials perform both technically and in our customers' markets.

100+ patents, 94 authorized patents, including 55 invention patents, and 10000+ cooperative customers.

8 major performance testing equipment

1.Thermal performance testing

2.emission detection

3.Photoelectric performance testing

4.Mechanical property testing

5.Flow performance testing

6.Flame retardant performance testing

7.Material Reliability Assessment

8.Material composition analysis

ISO9001-2015 Quality Management System

IATF16949 Automotive Industry Quality Management System

IECQ45001 Hazardous Substances Process Management System

ISO45001 Occupational Health Management System

ISO14001 Environmental Management System Intellectual Property Management System

No.2 Luhua Road,Boyan Science Park,Hefei,Anhui Province,China